Iingxaki eziqhelekileyo kunye nokugcinwa komatshini wokushicilela wedijithali

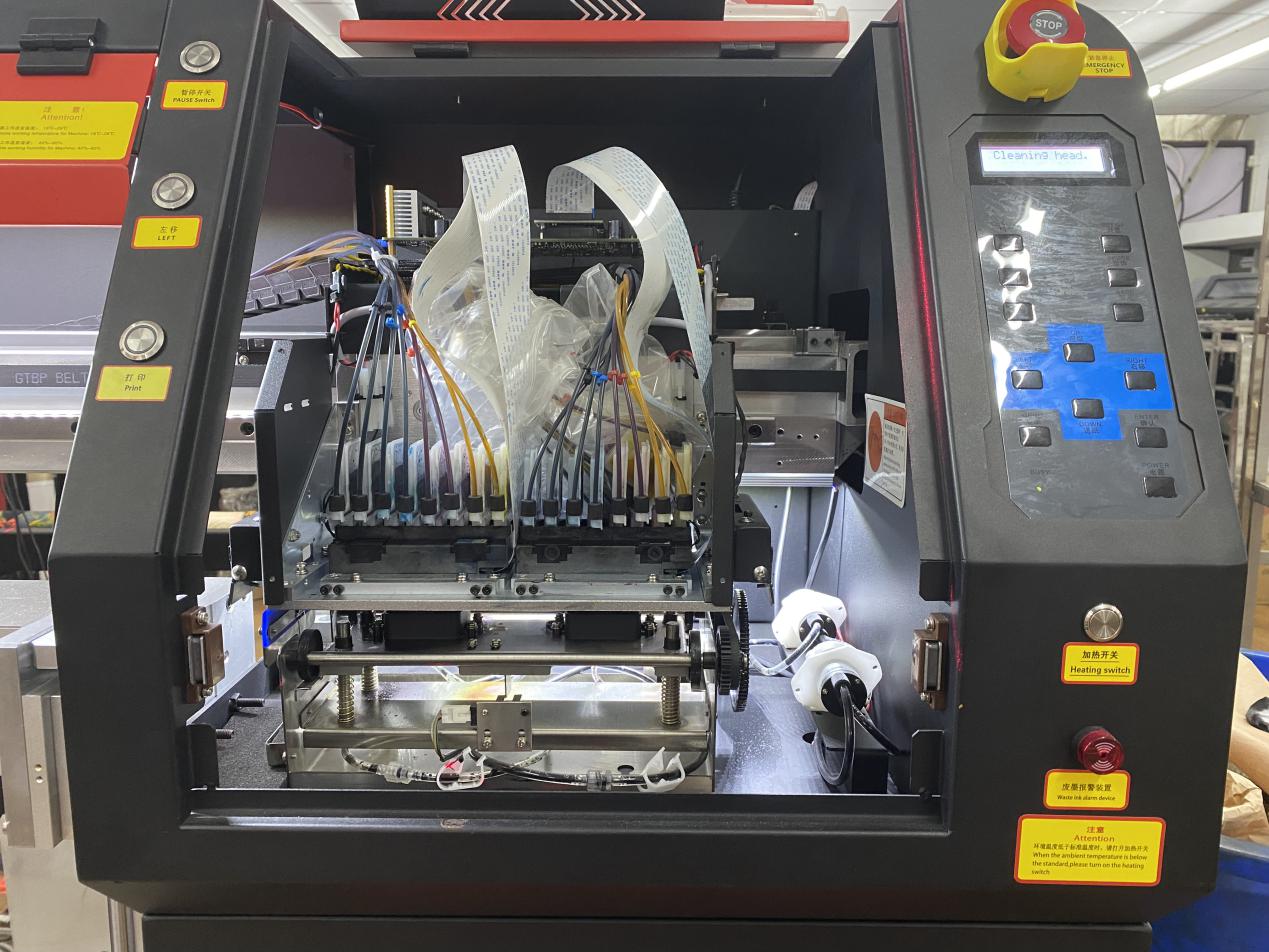

Kwinqanaba lobugcisa, ukuba sifuna ukuba iimveliso ezisemgangathweni eziphezulu ziprintiwe kakuhle, i-nozzles zomatshini wokushicilela yedijithali kufuneka isebenze ngokuqhelekileyo. Nge-nozzles emiselweyo, iziphumo ze-inki zinokwenza ngcono kwaye zinokuphuculwa ngakumbi. I-nozzle yinxalenye engenakuphikwa kwenxalenye yenkqubo yokuprinta yedijithali. Ikwayinxalenye ebiza kakhulu

Nangona kunjalo, ukuba umsebenzi awulunganga, i-nozzle inokwenzeka ukuba ibe nengxaki, ke zithini izizathu zokusilela kwengxolo yomatshini wokushicilela wedijithali?

Okokuqala, wonke umntu kufuneka azi ukuba i-inki luhlobo lolwelo ekulula ukuphelisa, kwaye kulula ukuba luguquguqukele emoyeni. Ngokuprinta, i-inki kufuneka ikhutshelwe emoyeni ukuze wenze umfanekiso wome. Ke ngoko, ukungaphumeleli okuqhelekileyo kukuqhekeka kwe-nozzle, kungenxa yokuqokelelwa kwe-inki kwimingxunya ye-nozzle ngaphandle. Kukho izizathu ezine eziphambili zokusilela kwe-nozzle.

Isizathu sokuqala kukuba ngexesha lokusetyenziswa kwemihla ngemihla kwe-nozzle yomatshini wokushicilela, xa i-nozzle ikhupha i-inki, ayinakukwazi ukuba i-inki ijikeleze, kwaye le nxalenye ye-inki iza kuhlala ijikeleze. Emva komile emoyeni, kumiselwa izinyibilikisi, kwaye ekuhambeni kwexesha ukuqokelela kwee-solids kuyakwenza imingxunya ye-nozzle incinci kwaye ibangele ukuba ibhloko ye-nozzle emngxunyeni.

Isizathu sesibini sokusilela kwe-nozzle: ukwaluphala kwezixhobo ze-elektroniki zesekethe yokuqhuba kunye nokuqokelelwa kwe-inki eyomileyo kunokuchaphazela i-nozzle engaphandle okanye Iziphumo ze-inki aziveli.

Isizathu sesithathu sokusilela kwe-nozzle: I-nozzle ayikhuselekanga xa i-inki itshintshwe, kwaye i-gump okanye umonakalo iya kuchaphazela imeko ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki ye-inki.

Isizathu sesine: ukusebenzisa i-nozzle ixesha elide kuya kubangela ukuba i-inki ihlale kwi-nozzle ixesha elide, ingakumbi izixhobo ezihlala zivaliwe ngenxa yexesha elingenasiphelo lomyalelo kwaye kulula ukuba ivunyelwe kwi Isihluzo sangaphakathi okanye udonga lwangaphakathi lwejelo le-inki. Ke icandelo elinqamlezileyo lendlela yokuhamba kwe-inki linokuba lincinci, likhokelela kwi-phenomenon ukuba i-nozzle ayikhupheli i-inki.

Ukuze wenze i-nozzle isebenze ngakumbi kwaye igudile, ulondolozo oluthambileyo, ukulungisa rhoqo kubalulekile!