Ngaba ucinga ukuba imveliso yokuprinta idijithali yemigca emnyama iya kuvela kuphela kwinkqubo yokuphuma kwamanzi? Uphilile ngoba kuya kubakho ukukhanya kunye nemigca emnyama eprinta yedijithali. Namhlanje siza kufunda indlela yokuthintela ukukhanya kunye nemigca emnyama xa ucinga ukuba ukuprinta idijithali yemigca emnyama kuya kuvela kuphela kwinkqubo yokuphuma kwemveliso? Uphilile ngoba kuya kubakho ukukhanya kunye nemigca emnyama eprinta yedijithali. Namhlanje siza kufunda indlela yokuthintela ukukhanya kunye nemigca emnyama kumshicileli wedijithali.Iprinta yedigital.

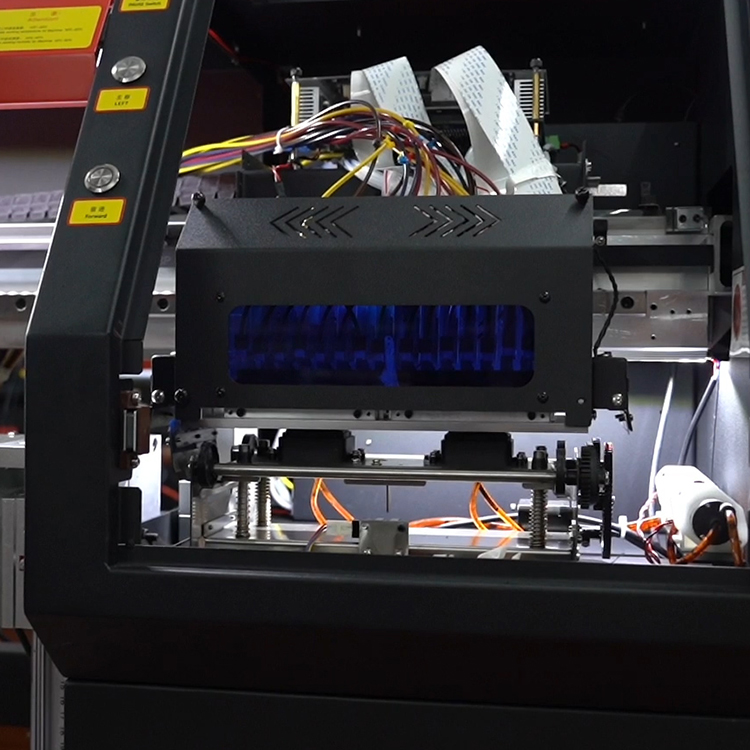

1. Sihlala sisithiumatshini wokushicilela wedijithaliI-nozzle kufuneka igcinwe kubomi bethu bemihla ngemihla, kuba i-nozzle ayisiyonxalenye ebalulekileyo yokuchaneka kwenqanaba langaphakathi lePrinta yedijithali, kodwa nexabiso layo lixabisa kakhulu, ke ukuntywila koomatshini kunye nokuntywila kuya kuthintelwa kwinkqubo xa usebenzisa umshicileli wedijithali.

2. I-nozzle yeprinta yedijithali incinci kakhulu, enokuthi ithethwe ukuba ibe ngobukhulu obufanayo njengothuli emoyeni, ke uthuli emoyeni kulula ukufaka i-nozzle. Ke ngoko, indawo yemveliso mayigcinwe icocekile kwaye icocekile.

3. Kufuneka kuthathelwe ingqalelo kwimeko yemveliso. Umshicileli wedijithali akufuneki asebenze kwinqanaba lobushushu obuphezulu, ekulula ukuhambisa iinxalenye zoomatshini kunye ne-nozzle; Kwangelo xesha, umahluko wamaqondo obushushu kwindawo yokusebenza akukho lula ukuba mkhulu kakhulu. Ukuba ubushushu bendawo yokusingqongileyo butshintsha ngokukhawuleza kakhulu, buya kubangela ukwandiswa kwe-thermal inani elikhulu lezinto zobunjineli kumatshini, zikhokelela ekunxibelweni kwamalungu am, kwaye kunokubangela i umgangatho wemveliso.

I-4. Khetha i-inki esemgangathweni ephezulu, kuba i-inki ye-inki engaphantsi, ekulula ukukhokelela kwi-nozzle block. Ityala elinzulu liya kukhokelela kumgaqo-nkqubo wonke.

I-5. Gcina iikhatriji ezingasetyenziswanga ixesha elide kwibhokisi ye-inki ukuthintela ibhlogo ye-nozzle.

6. Sukususa ngokulula i-nozzle, ukuthintela ukonakala kwiindawo ezichanekileyo. Ukuba kukho imfuneko, unokucela abasebenzi abaziingcali ukuba balungise.

7. Ukuba i-nozzle ivaliwe kancinane okanye ingenasitshisi okanye imibala, okanye ipateni ifihlwe phantsi kwesisombululo esiphezulu, kufuneka icocwe kwangoko ngenkqubo yakho yokucoca ngomatshini.

I-8. Kucetyiswa ukukhetha umgangatho ophezulu kunye ne-inki yoqobo kunye ne-inki ehambelana nayo. Uninzi lwabantu luya kukhetha i-inki ehambelana nendleko enkulu.

9. Ukuze i-nozzle iguqule ngcono kwi-inki entsha ehambelana nayo, kungcono ukuba isebenzise ngokupheleleyo i-inki yoqobo, yongeza i-inki ehambelana nayo okokuqala, ukutshiza isiqingatha sendlela Usuku. Ke ixesha ngalinye ngaphambi kokusetyenziswa ukwenza uvavanyo lokuzivavanya, ukuba iziphumo zovavanyo zokuzivavanya zilungile, ke ibonisa ukuba le i-inki ehambelanayo inokusetyenziswa ixesha elide. Apha kubalulekile ukuba uqaphele ukuba kungcono ukusebenzisa uphawu olunye emva kokukhetha i-inki ehambelana nayo.

Ukusuka kwindawo yembono ye-9 yokuthintela imigca emnyama kunye nokukhanya kumzobo womatshini wokushicilela wedijithali, ukubeka umsebenzi ofanelekileyo wolondolozo lwemihla ngemihla, ukwenzela ukuthintela uthotho lwe Iingxaki ezinje ngemigca eyaphukileyo, iibhloko, umnyama kunye neendlela ezimnyama nezikhanyayo kunye neziphithiphithi zombala.

I-Post Time: Aug-01-2022