Izinkinga ezijwayelekile kanye nokugcinwa komshini wokuphrinta wedijithali

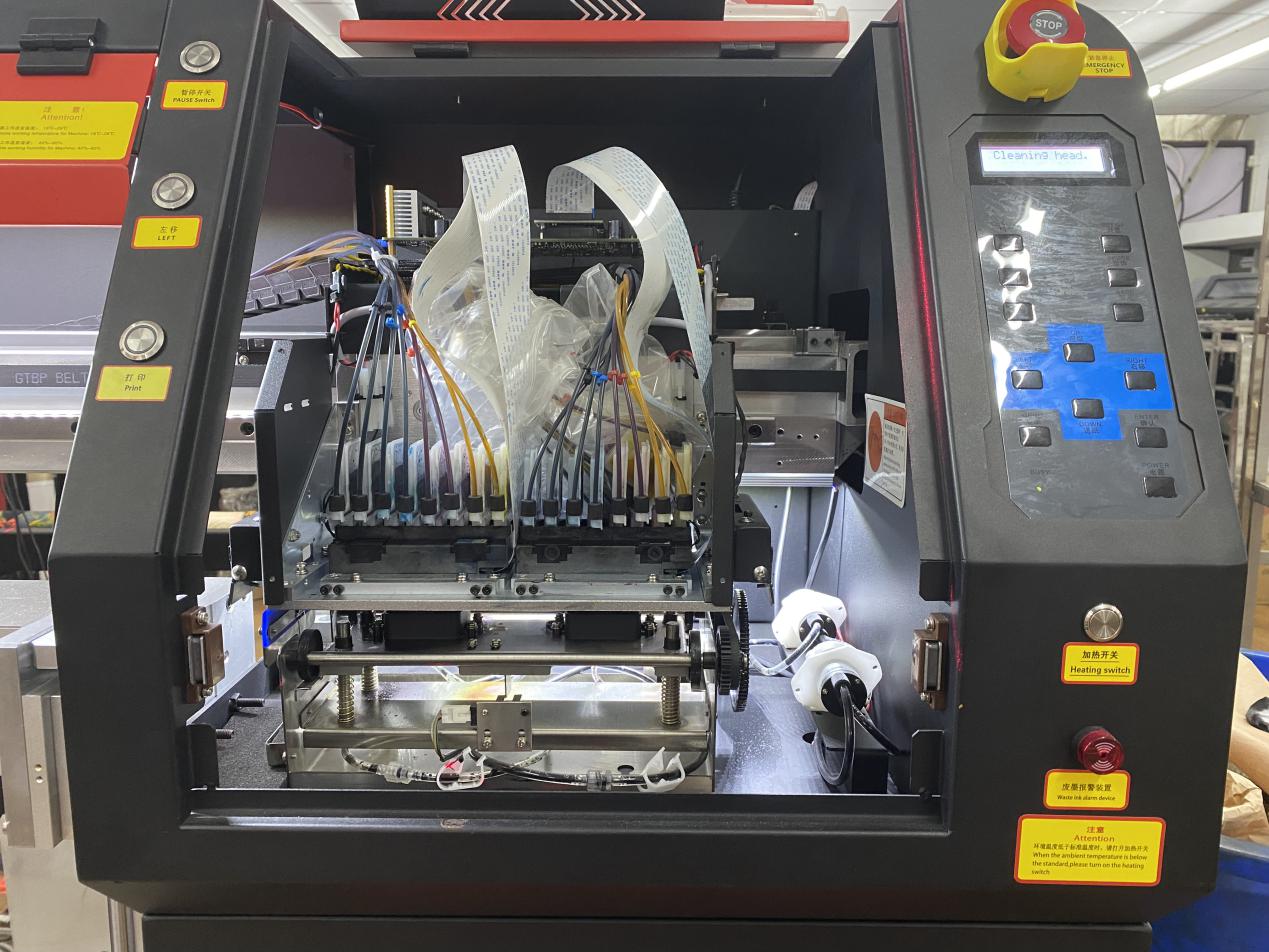

Ezingeni lobuchwepheshe, uma sifuna imikhiqizo esezingeni eliphakeme ephrintiwe kahle, ama-nozzles womshini wokuphrinta wedijithali kufanele asebenze ngokujwayelekile. Nge-nozzles enhle esezingeni elifanele, okukhishwayo kwe-Ink kungenza kangcono futhi kungahlanjululwa ngokwengeziwe. I-nozzle iyingxenye ebaluleke kakhulu yenqubo yokukhiqiza yedijithali. Futhi kuyinto ebizayo

Kodwa-ke, uma ukusebenza kungafanele, i-nozzle kungenzeka ibe nenkinga, ngakho-ke yiziphi izizathu zokwehluleka kwe-nozzle yomshini wokuphrinta wedijithali?

Okokuqala, wonke umuntu kufanele azi ukuthi uyinki uhlobo lwe-ketshezi okulula ukuhwamuka, futhi kulula ukuba lula ukushintshanisa emoyeni ukusula izinto eziqinile. Ekunyatheliseni, uyinki kufanele ukhishwe emoyeni ukwenza isithombe somile. Ngakho-ke, ukwehluleka okujwayelekile kwe-nozzle kuyinto blockage ye-nozzle, kungenxa yokuqongelelwa kwe-ink ezitsheni ze-nozzle ngaphandle. Bese kuba nezizathu ezine eziphambili zokwehluleka kwe-nozzle.

Isizathu sokuqala ukuthi ngesikhathi sokusetshenziswa kwansuku zonke kwe-nozzle yomshini wokuphrinta, lapho i-nozzle ekutholela i-inki ku-medium, akunakugwemeka ukuthi uyinki othile uzohlala uzungeze, futhi le ngxenye yale nksi izohlala izungeza. Ngemuva kokumiswa emoyeni, ama-solids ayakhiwa, futhi ngokuhamba kwesikhathi ukuqoqwa kwama-solids kuzokwenza izimbobo ze-nozzle zincane futhi zibangele ukuqhekeka komgodi we-nozzle.

Isizathu sesibili sokwehluleka kwe-nozzle: Ukuguga kwezingxenye ze-elekthronikhi ze-drive Circuit kanye nokuqongelela okuphelele kwe-inki ukungcola kungathinta i-voltage ye-volzage ye-drive nozzle, okuholele ekutheni i-nozzle ayiphumi uyinki noma Ukukhishwa kwe-Ink akusizi.

Isizathu sesithathu sokwehluleka kwe-nozzle: I-nozzle ayivikelekile lapho i-ink ithathelwa indawo, futhi i-bump noma ukulimala kuzothinta nesimo se-ink jet ye-nozzle.

Isizathu sesine: Ukusebenzisa i-nozzle isikhathi eside kuzodala ukuthi uyinki uzohlala kwi-nozzle isikhathi eside, ikakhulukazi imishini evalwa njalo ngenxa yesikhathi sokuhleleka futhi kulula ukuba ama-adsorbed ku- Isihlungi sangaphakathi noma udonga olungaphakathi lwesiteshi se-Ink. Ngakho-ke ingxenye yesiphambano yokugeleza kwe-ink ingaba mincane, okuphumela ekutheni kube namkhuba wokuthi i-nozzle ayikhiphi uyinki.

Ukuze wenze i-nozzle isebenze kahle futhi ibushelelezi, ukulungiswa okujwayelekile nokuhlanza kubalulekile!