30cm DTF Printer CO30

30cm DTF Printer CO30

CO30 DTF printer adopts a design that separates white ink from color ink. The white film has its own stirring system to prevent the white film from settling and blocking the nozzle. The feathering function makes the printed pattern more delicate. The CO30 uses an independent control panel, which is easier to operate. The upgraded paper feeding system and automatic winding system can achieve unattended operation. The ink and hot melt powder of the DTF printer have been tested by us and are the most matched, providing users with high quality and high productivity. This CO30 DTF printer is suitable for a variety of fabrics (cotton, polyester, leather, canvas, blended, etc.) and can provide you with a wider range of business scope.

Colorido, as a manufacturer of DTF printers, specializes in providing high-performance digital printing technology for small and medium-sized enterprises. Users do not need to worry about third parties charging additional fees. As a DTF printer manufacturer, we have an advantage. All our exported products come with a 1-year warranty (printheads are not covered by the warranty) and lifetime after-sales service

Model:CO30

Print Head:2Epson XP600

Print Width: 300mm

Color:CMYK+W

Printing Speed:6Pass 4m2/h

Print Media:Printing Film

Ink Type: Pigment Ink

RIP Software: Maintop, Flexiprint

Bag

Hat

Hoodie

Jeans

Application Scope

CO30 DTF printer has a print width of 300MM and is suitable for use at home or in a small business. It is suitable for a variety of fabrics (cotton, polyester, nylon, blended, leather, denim, etc.) and can transfer your designs to various garments and accessories.

White film stirring system: It comes with a white film stirring system, which makes it difficult for the white film to settle and cause blockage.

Air suction system: During the printing process, the air suction system can suck the paper to prevent movement and make the printed pattern more accurate.

Automatic powder feeding device: The hot melt powder is poured into the device, stirred, and evenly sprinkled on the printed heat transfer film. There is also a collection device at the bottom to reduce waste.

Air filter: An air filter is used to reduce the smoke generated by the heat transfer film and hot melt powder

Automatic winding system: The DTF powder shaking machine adopts automatic winding, which reduces manual winding and is more convenient

Independent operating system and LCD display: The independent operating system makes it easier for workers to operate, and the LCD display can more conveniently monitor in real time

Ink shortage alarm: When the ink reaches the critical point, an alarm will be issued to remind you to fill the ink, and you don’t need to check it frequently

Specifications

| Model | DTF printer CO30 | Printhead Quantity | 2 |

| Printhead | Epson XP600 | Print Width | 30CM |

| Nozzle Quantity | 1080 | Print Height | 2-5mm |

| Print Colors | CMYK+W | Max. resolution (DPI) | 1080dpi |

| Media | Pyrograph Film | Max speed CMYK(1.9m printing width, 5% feather) | 6pass 4m²/h |

| Ink Cycle | Auto White Ink Cycle | Ink Supply Method | Siphon Positive Pressure Ink Supply |

| Bulk Tank Capacity | 220ML | Material Transmit | Single Motor System |

| Ink Type | Pigment Ink | Max. Media Taking up (40g paper) | 100m |

| Computer System | Win7/Win10 | File Forms | TIFFJPG, EPS,PDF, etc. |

| Operate Environment | Temp.: 15°C-30°C,Humidity:35°C-65C | RIP Software | Maintop, Flexiprint |

| Printer Size | 1720*650*1400mm | GW(KGS) | 210 |

| Package Size | 1200*650*620mm | Computer Configuration | Hard Disk: HARD DISK: 500G or more, |

| Power Supply | 210V,50/60HZ,10A | GPU: ATI Discrete GPUMemory: 8G or more, CPU: Inteli5 Processor | |

| Print Power: 1000W | Dryer Power: Max.3500W |

DTF Printer Performance Features

The following are some details about DTF printer, so that you can better understand this device

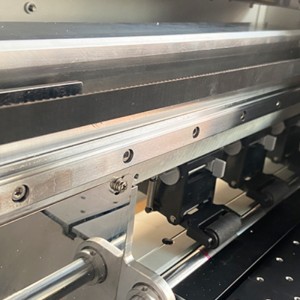

Carriage

The DTF printer CO30 carriage is equipped with two Epson XP600 nozzles. Anti-collision devices are installed on both sides of the carriage to prevent foreign objects from being encountered during the printing process.

INK Tank

The ink of DTF Printer CO30 is composed of five colors: CMYK+W, and the white ink is equipped with a separate white ink mixing system. For special needs, we can also add fluorescent colors

Paper Pressure Roller

Accurate paper pressingto ensure printing patternss tability

Automatic Winding System

DTF printer CO30 adopts automatic winding, which can significantly reduce paper wrinkles, reduce labor, and is more efficient and convenient.

Mesh Belt Transmission

DTF printer CO30 adopts mesh belt transmission to ensure that the heat transfer film remains even during the entire transportation process, avoids wrinkles during the drying process, avoids losses, and improves production capacity.

2Epson XP600

DTF printer CO30 uses 2 Epson xp600 print headsStable quality, corrosion resistance, ready-to-use, printing clear.

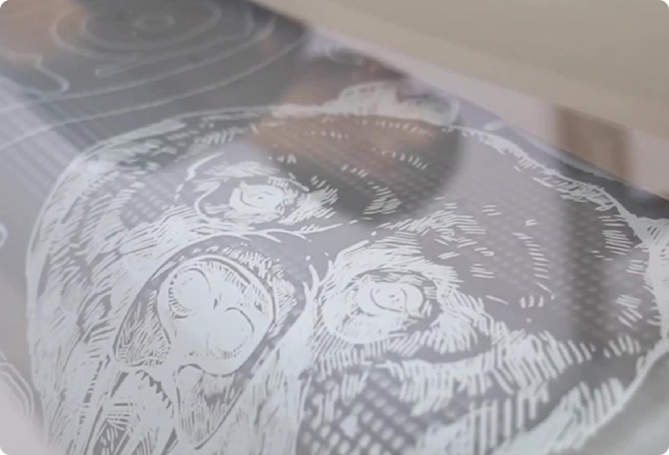

DTF Printing Process

The following is the workflow of a DTF printer:

1. Prepare the design drawing according to the size of the product. If a spot color channel is required, prepare the channel color.

2. Import the completed design artwork into the RIP software for RIP. Then import the RIPed pictures into the printing software for printing.

3. Before printing, run a test strip to see if the nozzle is in the best condition.

4. Cut out the printed pattern and place it on the object that needs to be transferred. The temperature should be between 170℃-220℃.

5. Place the thermally transferred product aside to cool. After cooling, peel off the thermal transfer film.

DTF Printer VS Screen Printing

What are the benefits of Dtf to transform traditional processes into DTF thermal transfer printing?

o Smaller footprint

o The operation is simpler and the shipment rate is higher

o No pre-processing required, direct transfer

o Press and iron a finished garment in less time

o Only one person is needed to operate it, no redundant labor is required

You May Need

After purchasing a DTF printer, you may also need to purchase some consumables:

o DTF hot melt powder(The function of hot melt powder is to completely transfer the pattern to the object after high temperature)

o DTF INK(The ink we recommend our customers to use is the one that achieves the best results after our testing.)

o DTF Transfer Paper(30cm transfer paper is used)

o Humidifier(Recommended when the air humidity is less than 20%)

o Air Purifier

Our Service

Buy a Colorido printer to enjoy the following services

3-Month Warranty

3-month warranty is provided after purchasing DTF printer CO30 (print head, ink, and some consumable products are not covered by the warranty)

Installation service

can support engineers on-site installation and online video guidance

24-hour online service

24-hour online after-sales service. If you encounter problems and need us, we are online 24 hours a day.

Technical training

After purchasing the machine, we provide training on the use and maintenance of the machine, which allows customers to quickly get started and solve some minor problems.

Accessories provided

We will provide customers with a certain amount of wearing accessories to ensure that if problems arise during use, parts can be replaced in time without delaying production.

Upgrade equipment

When we have new features, we will provide customers with upgrade plans

FAQ

DTF printer has fast printing speed and simple operation. One person can operate the machine and no pre-processing is required.

The maximum printing size of this CO30 is 30CM. Of course, if you need a larger size, please contact sales. We also have larger size machines.

Sure, we just need to add fluorescent ink. Then just set it in the spot color channel of the picture.

You can put forward your idea and we will give it to our engineers, if it can be realized, it can be customized

After placing the order, the delivery time is one week. Of course, if there are special factors, we will notify you in advance.

We can transport by sea, air or rail. It depends on what you need to choose. The default is sea transport.