22 Years Factory Sock Printing Machine -CO-80-1200 Export to Maldives

Out of Stock

22 Years Factory Sock Printing Machine -CO-80-1200 Export to Maldives Detail:

Sock Printing Machine -CO-80-1200

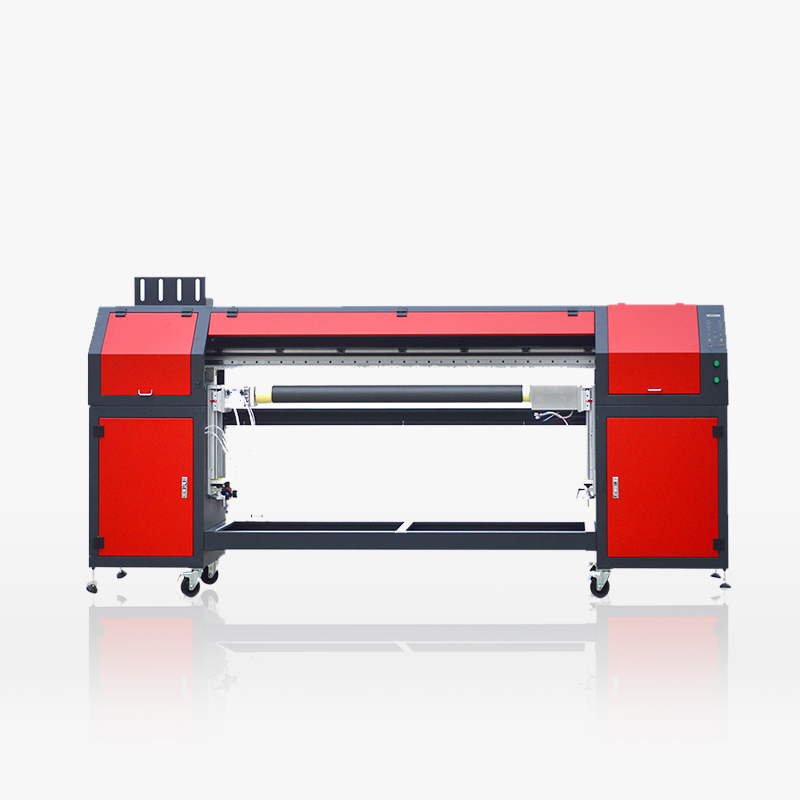

The socks printing machine is the high-tech digital printing technology, which is specially designed for socks manufacturing industry to print customized socks according to customer’s requests. One of the most important character of socks printer is the seamless connection for printing. It means that any shape, size and pattern designed artwork could be printed on the socks perfectly without any seamless connection via the sock’s printer.

The printing process for socks printing is very simple, just put the socks on the roller which set up at the machine, then control the machine to connect with the software, then machine will start doing the operation. It is not only having the capability to easy achieve vibrant color printing on socks by the digital printing technology, but also adapt various cartoon pattern designs, painting of fruits, flowers, etc., and the company logos and brand names with clear outlines as well.

Application Scope

The socks printer is no longer just for printing socks only! Nowadays, it can also print a variety of 360-degree seamless printing products such as yoga leggings and sleeve cover and other seamless tubes products to achieve more diversified printing demands.

Product Parameters

| Model No. | CO-80-1200 |

| Print Mode | Scanning Type Printing |

| Media Length Request | Maximum:1200mm |

| Max Output | <500mm Diameter/2Pcs per time |

| Media Type | Poly /Cotton/Wool/Nylon |

| Ink Type | Disperse,Acid,Reactive |

| Voltage | AC110~220V 50~60HZ |

| Machine Meas.&Weight | 2930*580*1280mm/300kg |

| Ink Color | CMYKLC LM OR BL GY Y(Optional) |

| Print Head | EPSON DX5 |

| Print Resolution | 720*600DPI |

| Production Output | 30-40 pairs /H |

| Printing Height | 5-20mm |

| RIP Software | Neostampa |

| Interface | Ethernet port |

| Roller Size | 70/80/220/260/330/360/500(mm) |

| Package Dimension | 3050*580*1520mm/430kg |

| Operation Requests | 20-30℃/ Humidity :40-60% |

Features & Advantages

The socks printer is a highly efficient and environmental protection equipment, can directly print any designs of patterns, text, etc. on socks. It has the advantages of low cost, high efficiency, and personalized customization. The appearance of sock’s printer has brought new opportunities to the sock customization industry.

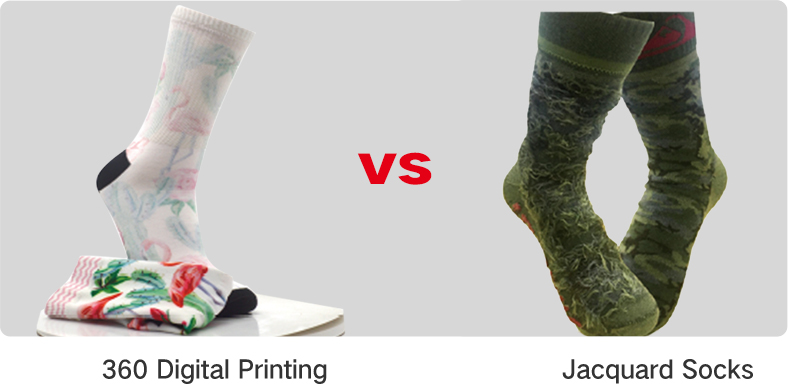

Printing Socks VS Jacquard Socks & Flat Sublimation Socks

Digital printing socks has tremendous advantages compare with ordinary jacquard socks and sublimation socks. Such as customization, multifunction, fast print, vibrant colors, good color fastness, environmental production and strong adaptability.

Digital Printing Socks VS Jacquard Socks

Ordinary jacquard socks could not avoid the loose threads at reverse side of socks, if with multi-designed details, also it brings uncomfortable once wearing.

Digital Printing Socks VS Flat Sublimation Socks

There is obvious connection seam for the patterns on flat sublimation press socks, while 360 seamless printing socks could perfectly solve this problem and make design without any connection seams.

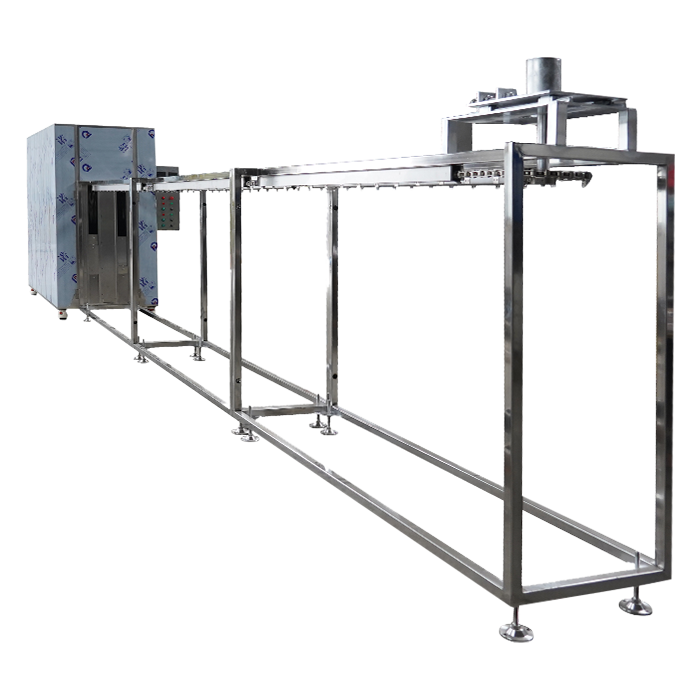

After-treatment Euquipments

Colorido specializes in providing solutions to customers. The following are some equipment needed in the sock production process, sock ovens, sock steamers, washing machines, etc.

Industrial Dryer

The dryer adopts an automatic control device, and the time is adjusted through the control panel to automatically complete the entire drying process.

Industrial Washing Machine

Industrial washing machine, suitable for textile products. The inner tank is made of stainless steel. The size can be customized according to needs.

Industrial dehydrator

The inner tank of the industrial dehydrator is made of stainless steel and has a three-legged pendulum structure, which can reduce vibrations caused by unbalanced loads.

Upgraded Version Of Oven

The upgraded version of the sock drying oven has extended the length of the chain. Can be used by more socks printing machines. The oven can be customized according to customer needs

Process Step

How to make Polyester socks

After Sales Service

1. Provide a complete after-sales service program, including equipment warranty, maintenance, breakdown repair, etc., to ensure that customers don’t have any worries during operating the machine.

2. Establish a professional after-sales service team to classify and deal with different issues, efficiently solve various problems, and optimize customer experience.

3. Provide live technical support services, respond to customer questions and communicate through various channels such as teams video call, telephone conversation, email, and online customer service.

4. Establish a complete spare parts inventory system to provide customers with the required accessories and repair parts in time to ensure the rapid maintenance and good operation of the equipment.

5. Regular equipment maintenance and upgrading system support, provide equipment maintenance guidance and operation training and other services, so that customers can better understand and get better using for socks printing machines.

Product Show

FAQ

1. What is a socks printer? what it can do?

The 360 seamless digital printing machine is an all-in-one printing solution equipped to handle a wide range of seamless products. From yoga leggings, sleeve cover, knitting beanies, and buff scarfs, this printing machine uses seamless technology to deliver high-quality, vibrant prints. Its multi-functional capabilities provide users with more options to achieve their desired results.

2. Can the socks printer print on demand? Is it possible to customize the design?

YES,The 360 seamless digital printing machine has no MOQ requests, does not require print mold development and supports on-demand printing, and can be customized products.

3. What kind of patterns can the socks printer print? Is it possible to print multiple colors?

The sock printer can print any pattern and design you want to print, and it can be printed in any color

4. What is the printing effect of the socks’ printer? Is it clear and durable?

The socks printed by the socks printer have been tested for color fastness reach to grade 4, wear-resistant and washable

5. How to operate the socks printer? Are specialized skills required?

The innovative sock printing machine is designed with user-friendliness in mind, allowing for easy operation and quick setup time. Whether you prefer to learn online or offline, our comprehensive training program and support team are available to ensure a seamless experience. With its advanced features and capabilities, this printer is sure to enhance your socks’ appeal while meeting all your printing needs.

6. What does the after-sales service of socks printer include? Do you provide technical support and training?

We offer an all-inclusive post-sales service program, comprising gear guarantee, upkeep, breakdown fixes, etc., to guarantee that customers utilize the hardware with complete peace of mind.

Product detail pictures:

Related Product Guide:

What Is UV Flat-Panel Printer?

Do You Know the Printing in China?

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for 22 Years Factory Sock Printing Machine -CO-80-1200 Export to Maldives , The product will supply to all over the world, such as: Toronto, Luxembourg, Dominica, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.