60cm DTF Printer C070-3

60cm DTF Printer C070-3

DTF printer CO70-3 uses 3 new generation Epson I3200-A1 print heads, automatic rewinder, and independent oven. This machine has been professionally upgraded to continuously print colorful and bright patterns.

When operating the DTF printer, it is best to operate in a well-ventilated area, or equipped with an air purifier. Observe the indoor temperature and humidity. DTF ink and heat transfer film require suitable humidity. It is recommended that the temperature is 20°C and the humidity is 40%. , this will reduce the risk of ink blocking the nozzle and the heat transfer film getting wrinkled.

Advantages of using DTF printer

The working principle of DTF is to transfer the printed heat transfer film to various items or clothing. It has the following advantages:

• Applicable to a wide range of materials: can be applied to cotton, nylon, polyester, blended and other materials.

• Can be used on white and dark clothing.

• CMYK+W five color combinations, fluorescent colors can be customized.

• Upgraded 3 I3200-A1 print heads, improved printing speed and accuracy, and increased production capacity.

• Can support mass production without pre-processing.

Product Parameters

| Model | 60cm DTF printer CO70-3 |

| Printhead | Epson 13200-A1 |

| Print Colors | CMYK+W |

| Print Height | 2-5mm |

| Media | Pyrograph Film |

| Max speed CMYK(1.9m printing width, 5% feather) | 6pass 8m²/h 8pass 6m²/h |

| Ink Cycle | Auto White Ink Cycle |

| Material Transmit | Single Motor System |

| Transmission | Gigabit LAN |

| Computer System | Win7/Win10 |

| Operate Environment | Temp.: 15°C-30°CHumidity:35°C-65C |

| Printer Size | 1865*676*1480mm |

| Package Size | 2060*990*960mm |

| Print Power: | 1000W |

| Nozzle Quantity | 3200 |

| Print Width | 600mm |

| Printhead Quantity | 3 |

| Max. resolution (DPI) | 3200dpi |

| Ink Supply Method | Siphon Positive Pressure Ink Supply |

| Bulk Tank Capacity | 220ML |

| Ink Type | Pigment Ink |

| Max. Media Taking up (40g paper) | 100m |

| File Forms | TIFF,JPG, EPS, PDF, etc. |

| RIP Software | Maintop, Flexiprint |

| GW(KGS) | 205 |

| Power Supply | 210-230V,50/60HZ,16A |

| Dryer Power: | Max.3500W |

DTF Printer Performance Features

The following are some details of the powder shaking machine:

Pre-Drying/Correction

The pre-drying of the DTF printer can ensure that the ink will not agglomerate due to too much humidity when powdering, which will make the subsequent production process more convenient.

Carriage

The carriage of DTF printer is equipped with two Epson I3200-A1 print heads, which has higher printing accuracy. The I3200-A1 print head has a favorable price and has a longer service life than other print heads.

Ink Tank

CO70-3DTF Printer uses a 1.5L large ink cartridge and is equipped with 5 CMYK+W colors. We can also upgrade the fluorescent color if the user needs it. Wider printing range to meet more user needs.

Independent Oven

DTF printer CO70-3 is equipped with an independent oven, making the subsequent process simpler and more convenient.

Dtf Powder Shaker Purifier

Dtf powder shaker purifier enables you to work in any environment and provides a clean and smoke-free working environment

2Epson I3200-A1

DTF printer CO60 uses two Epson I3200-A1 nozzles. The nozzles provide more accurate and clear printing results, improving printing capabilities. The I3200-AI is more usable and more durable. It has strong compatibility and can be used with a variety of inks.

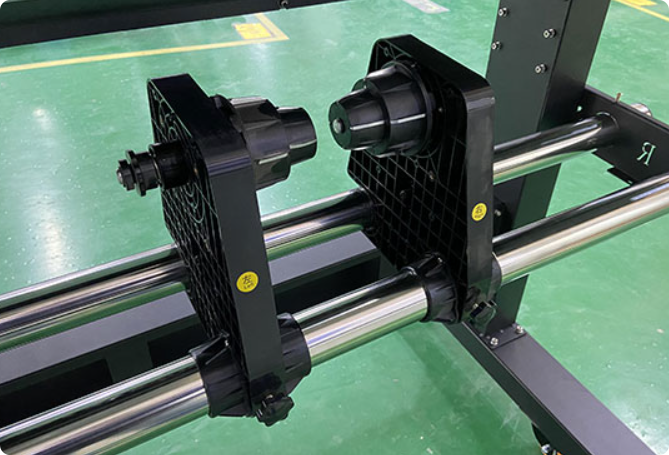

Feed & Take-up System

The automatic feeding and rewinding system makes it easier for the paper to enter the printer for printing more smoothly. Reduce manual sorting.

Mesh Belt Transmission

The mesh belt conveyor allows the material to be heated more evenly, and the heat transfer film will not be wrinkled or not dried due to uneven heating.

Application Scenarios

The application of DTF printer products can be seen everywhere in daily life:

Bottle

Phone Case

T-Shirt

Hat

Advantages of DTF printing

DTF's diversification, high-quality printing, on-demand printing and other advantages are deeply loved by users.

o DTF printing can be customized and personalized to meet the needs of different customers.

o Digital production improves production efficiency and frees up labor. reduce manufacturing cost.

o Energy saving and environmental protection. No waste ink is produced and no pollution to the environment. Produced on demand, no waste in the entire process.

o Press and iron a finished garment in less time

o The printing effect is good. Because it is a digital picture, the pixels of the picture can be improved and the saturation of the color can be modified according to requirements, which can better meet people's pursuit of picture quality.

DTF Printing Process

The following is the workflow of a DTF printer:

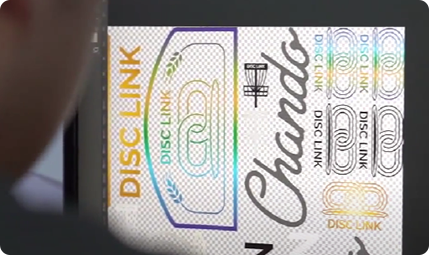

Design

Layout artwork according to size to minimize material loss.

Color Management

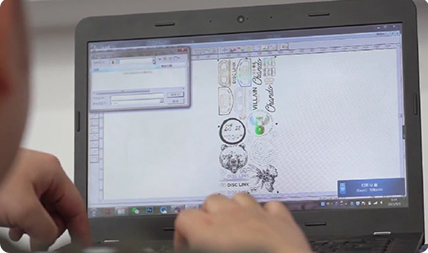

Import the finished pictures into RIP software for color management.

Printing

Import the color-managed pictures into the printing software for printing.

Apply Hot Melt Powder

Turn on the automatic powdering device, and the hot melt powder will be evenly sprinkled on the heat transfer film.

Heating

The heat transfer film coated with hot melt powder is dried and heated through the mesh belt, and the hot melt powder melts and adheres to the heat transfer film

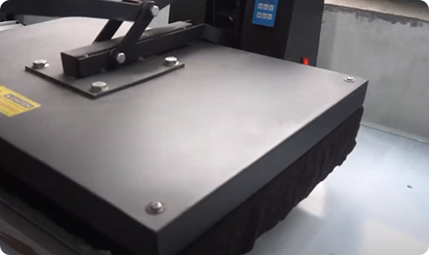

Transfer

Cut the printed material and align the objects to be transferred, 160℃/15S.

Finish

Thermal transfer products have bright colors, high color fastness and are not easy to crack.

You May Need

After purchasing a DTF printer, you may also need to purchase some consumables:

o DTF hot melt powder(The function of hot melt powder is to completely transfer the pattern to the object after high temperature)

o DTF INK(The ink we recommend our customers to use is the one that achieves the best results after our testing.)

o DTF Transfer Paper(30cm transfer paper is used)

o Humidifier(Recommended when the air humidity is less than 20%)

o Air Purifier

Our Service

Buy a Colorido printer to enjoy the following services

3-Month Warranty

3-month warranty is provided after purchasing DTF printer CO30 (print head, ink, and some consumable products are not covered by the warranty)

Installation service

can support engineers on-site installation and online video guidance

24-hour online service

24-hour online after-sales service. If you encounter problems and need us, we are online 24 hours a day.

Technical training

After purchasing the machine, we provide training on the use and maintenance of the machine, which allows customers to quickly get started and solve some minor problems.

Accessories provided

We will provide customers with a certain amount of wearing accessories to ensure that if problems arise during use, parts can be replaced in time without delaying production.

Upgrade equipment

When we have new features, we will provide customers with upgrade plans

FAQ

DTF printer has fast printing speed and simple operation. One person can operate the machine and no pre-processing is required.

The maximum printing size of this CO30 is 30CM. Of course, if you need a larger size, please contact sales. We also have larger size machines.

Sure, we just need to add fluorescent ink. Then just set it in the spot color channel of the picture.

You can put forward your idea and we will give it to our engineers, if it can be realized, it can be customized

After placing the order, the delivery time is one week. Of course, if there are special factors, we will notify you in advance.

We can transport by sea, air or rail. It depends on what you need to choose. The default is sea transport.