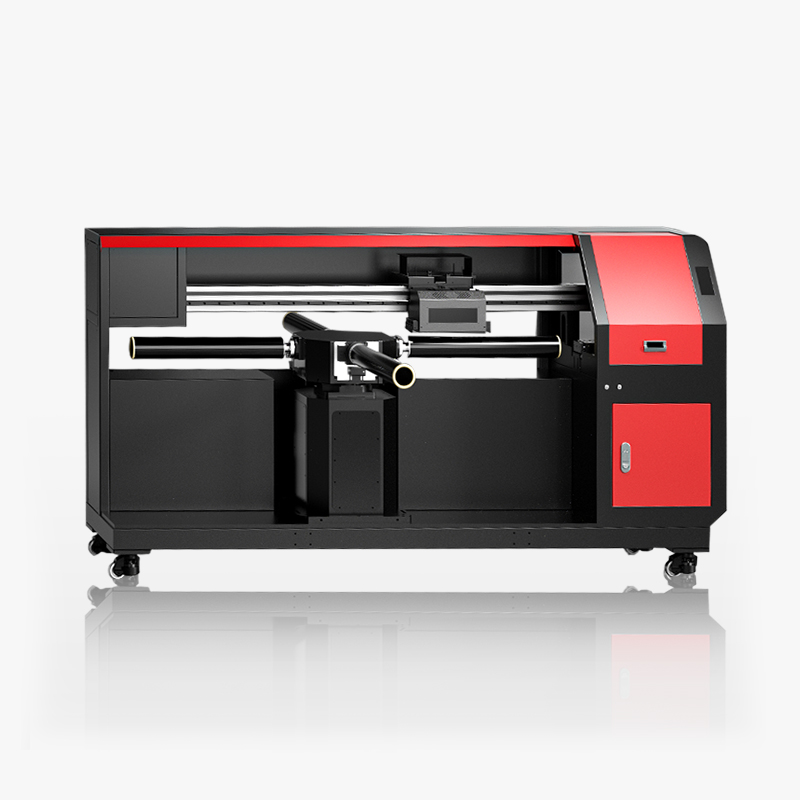

Socks Printing Machine CO-80-210PRO

Professional Socks Printer Manufacturer

CO-80-210Pro socks printer uses a four-roller rotating printing mode, which is biggest difference from previous generation of socks printer, that not necessary to remove the rollers from the sock’s printer anymore. With the engine drives the roller turn automatically to proper position for printing, it not only increased the convenience but also improved the printing speeds. Besides, the RIP software also upgrades to latest version, the color accuracy has been significantly improved, to guarantee the high printing resolution.

Features & Advantages

The new generation socks printer has significant improvements in both hardware and software. The following points are the main changes for this new generation of socks printer:

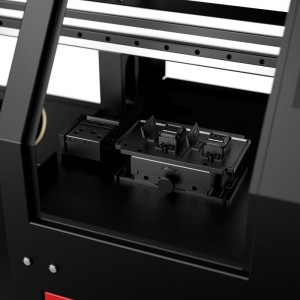

2units Of I1600 Print Heads

The socks printer is equipped with 2units of I1600 print heads, which support big amount of production output and with high image quality in 600DPI, could deliver high resolution images.

Upgraded Large Cartridge

Colorido digital socks printer adopts continuous ink supply system, upgraded large ink cartridges for longer use time. The continuous ink supply system effectively prevents ink blockage in the printhead and protects the service life of the printhead.

Four-Tube Rotation

Colorido digital printing socks printer uses a four-tube rotating printing method for printing. The four tubes are used in a circular manner, so that the machine is in a full-load working state, with a production capacity of up to 60-80 pairs per hour.

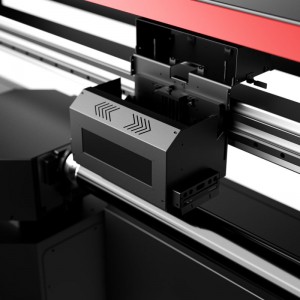

PLC Control System

Colorido digital socks printer uses an independent PLC control system, which makes it easier to control the machine and allows you to directly observe the printing status of the machine on the display screen.

Nozzle Heating

The head of the socks printer is upgraded with a heating plate, which can ensure the normal ink discharge of the nozzle in cold weather and is not prone to clogging.

Control Panel

Socks printer has a separate control panel, where you can perform some routine operations, such as cleaning the printhead, moving the carriage, etc.

Pedals

Double pedal design, you can step on the pedal when adjusting the socks, and rotate the roller to adjust the position of the socks

Industrial Square Rail

Socks printer uses industrial square rails, which makes printing socks more stable and increases the accuracy of pattern printing.

Machine Parameters

| Model No./: | CO-80-210PRO |

| Media Length Request: | Maximum:65cm |

| Max Output: | 73~92mm |

| Media Type: | Poly /Cotton/Wool/Nylon |

| Ink Type: | Disperse,Acid,Reactive |

| Voltage: | AC110~220V 50~60HZ |

| Printing Height: | 5~10mm |

| Ink Color: | CMYK |

| Operation Requests: | 20-30℃/ Humidity :40-60% |

| Print Mode: | Spiral Printing |

| Print Head : | EPSON 1600 |

| Print Resolution: | 720*600DPI |

| Production Output: | 60-80 pairs /H |

| Printing Height: | 5-20mm |

| RIP Software: | Neostampa |

| Interface: | Ethernet port |

| Machine Meas.&Weight: | 2765*610*1465mm |

| Package Dimension: | 2900*735*1760mm |

After-treatment Euquipments

Colorido specializes in providing solutions to customers. The following are some equipment needed in the sock production process, sock ovens, sock steamers, washing machines, etc.

Industrial steamer

The industrial steamer is made of stainless steel and has 6 built-in heating tubes. It is tailor-made for making cotton socks and can steam about 45 pairs of socks at one time.

Socks Oven

The sock oven is made of stainless steel and is rotary, which can dry socks continuously. In this way, one oven can be used by 4-5 socks printing machines.

Cotton Socks Oven

The cotton socks drying oven is made entirely of stainless steel and is tailor-made for drying cotton socks. It can dry about 45 pairs of socks at a time and is easy to operate.

Industrial Dryer

The dryer adopts an automatic control device, and the time is adjusted through the control panel to automatically complete the entire drying process.

Industrial Washing Machine

Industrial washing machine, suitable for textile products. The inner tank is made of stainless steel. The size can be customized according to needs.

Industrial dehydrator

The inner tank of the industrial dehydrator is made of stainless steel and has a three-legged pendulum structure, which can reduce vibrations caused by unbalanced loads.

Application Scope

Socks printer has various application scope, not only for socks printing, but can also print on other knitted tubular products, such as sleeve covers, head band etc. This multi-function expands the potential market with customers’ various demands.

Fire Series

Flower Series

Landscape Series

Gradient Series

Cartoon Series

Fruit Series

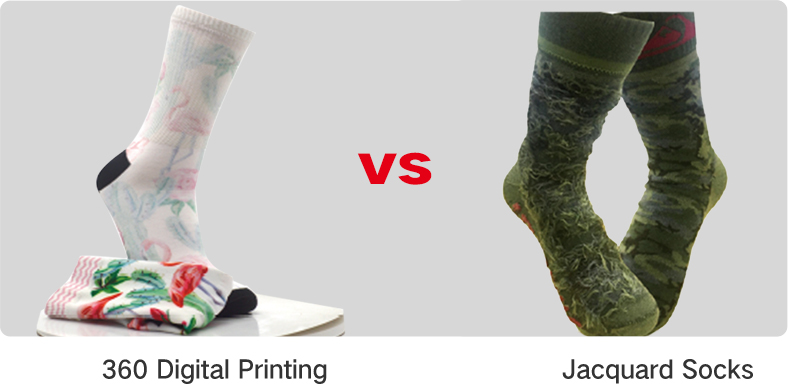

Printing Socks VS Jacquard Socks & Flat Sublimation Socks

Digital printing socks has tremendous advantages compare with ordinary jacquard socks and sublimation socks. Such as customization, multifunction, fast print, vibrant colors, good color fastness, environmental production and strong adaptability.

Digital Printing Socks VS Jacquard Socks

Ordinary jacquard socks reverse side has pretty much loose threadswhile 360 seamless printing socks never has this problem.

Digital Printing Socks VS Flat Sublimation Socks

There are obvious connection line for the patterns on sublimationpress socks , while 360 seamless printing socks could show 100%perfect design without connection line.

How to make Polyester socks

1.Printing

Iinput the ready AlP file to theprinting software and start for printing.

2.Heating

Put the printed socks into the oven to get the colorfixation, the temperature at 180 C time 3-4 minutes

3.Process Completed

Pack up the printed socks and send them to the customer.The whole process of polyester socks is finished

After Sales Service

1. Provide a complete after-sales service program, including equipment warranty, maintenance, breakdown repair, etc., to ensure that customers don’t have any worries during operating the machine.

2. Establish a professional after-sales service team to classify and deal with different issues, efficiently solve various problems, and optimize customer experience.

3. Provide live technical support services, respond to customer questions and communicate through various channels such as teams video call, telephone conversation, email, and online customer service.

4. Establish a complete spare parts inventory system to provide customers with the required accessories and repair parts in time to ensure the rapid maintenance and good operation of the equipment.

5. Regular equipment maintenance and upgrading system support, provide equipment maintenance guidance and operation training and other services, so that customers can better understand and get better using for socks printing machines.

Product Show

FAQ

The 360 seamless digital printing machine is an all-in-one printing solution equipped to handle a wide range of seamless products. From yoga leggings, sleeve cover, knitting beanies, and buff scarfs, this printing machine uses seamless technology to deliver high-quality, vibrant prints. Its multi-functional capabilities provide users with more options to achieve their desired results.

YES,The 360 seamless digital printing machine has no MOQ requests, does not require print mold development and supports on-demand printing, and can be customized products.

The sock printer can print any pattern and design you want to print, and it can be printed in any color

The socks printed by the socks printer have been tested for color fastness reach to grade 4, wear-resistant and washable

The innovative sock printing machine is designed with user-friendliness in mind, allowing for easy operation and quick setup time. Whether you prefer to learn online or offline, our comprehensive training program and support team are available to ensure a seamless experience. With its advanced features and capabilities, this printer is sure to enhance your socks' appeal while meeting all your printing needs.

We offer an all-inclusive post-sales service program, comprising gear guarantee, upkeep, breakdown fixes, etc., to guarantee that customers utilize the hardware with complete peace of mind.