Dye-Sublimation Printer 2Heads CO1900

Sublimation Printer 2Heads CO1900

The CO1900 dye-sublimation printer uses two I3200-A1 nozzles, which can produce clothing and decorative printing in large quantities. The machine can be left unattended, reducing downtime and maximizing production capacity.

Model: COLORIDO dye-CO1900 Sublimation Printer

Printhead Quantity: 2

Printhead: Epson 13200-A1

Print Width: 1900mm

Print Colors: CMYK/CMYK+4 COLORS

Max.resolution (DPI) :3200DPI

Max speed CMYK: 3pass 64m/h

Ink Type: Sublimation Ink,Water Based Pigment Ink

RIP Software: Printfactory, Maintop, Flexiprint, Onyx, Neostampa

Improve production capacity be more stable and precise

Adopt high-progress Epson I3200-A1 print head technology

The CO1900 dye-Sublimation Printer print head has extremely high color reproduction capabilities and high precision. The fastest printing speed is 64m² per hour, and CO1900 can achieve unattended, all-day production capabilities.

Flag Printing | Sports Apparel | Fabric | Decor | Signage | Custom Products

Product Parameters

| COLORIDO CO 1900 Sublimation Printer | |

| Printhead:Epson 13200-A1 | Nozzle Quantity:3200 |

| Printhead Quantity:2 | Print Width:1900mm |

| Print Colors:CMYK/CMYK+4 COLORS | Print Height:2-5mm |

| Max.resolution(DPI):3200DP | Media Transmit:Auto Taking-up Meida Device |

| Max speed CMYK(1.9m printing width, 5% feather):3pass 64m²/h | Drying Method:Extra Dryer Device |

| Ink Supply Method:Siphon Positive Pressure Ink Supply | Head MoistureMethod:Auto Head Cleaning and Moisturizing |

| Print Media:Transfer Paper | Bulk Tank Capacity:3L |

| Material Transmit:Dual Motors System | Ink Type:Sublimation InkWater Based Pigment Ink |

| Transmission Interface:Gigabit LAN | Max. Media Taking up (40g paper):200M |

| Max. Media Feeding(40g paper):300M | Computer System:Win7 64 Bit / Win10 64 Bit |

| File Forms:TIFF,JPG, EPS,PDF, etc. | Operate Environment:Temp.: 15°C-30°CHumidity:35°C-65°C |

| RIP Software:Printfactory, Maintop, Flexiprint, Onyx, Neostampa | Printer Size:2895*840*1490mm |

| GW(KGS):350 | Package Size:3000*940*1000mm |

| Power Supply:210-230V50/60HZ,16A | Dryer Power: Max.3500W |

| Print Power: 1000W | |

| Computer Configuration:Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk: WG500G GPU: ATI Discrete GPUMemory: 4G, CPU: Intel 15/17, G-Ethernet | |

| Standard Configuration | Ink Level Alarm System |

Detailed Display Of Sublimation Printer

The following are some details about sublimation printers

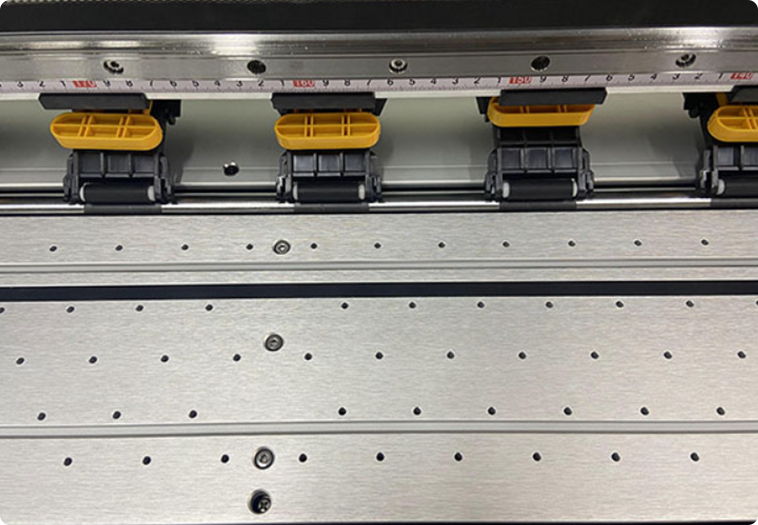

Carriage

The CO1900 dye-sublimation printer uses two Epson I3200-A1 print heads. The two sides of the carriage are equipped with anti-collision devices, which can play a protective role during the printing process.

Ink Tank

The CO1900 dye-sublimation printer has upgraded large ink cartridges and adopts a continuous ink supply system, which can provide uninterrupted ink to the nozzle and is not easy to clog, making the ink smoother.

Industrial Guide Rail

The use of industrial guide rails makes the carriage run more stably, without shaking caused by high-speed printing, and improves the printing accuracy of the printer.

Adsorption Platform

The dye-sublimation printer uses a vacuum adsorption platform, which can absorb the paper during printing to prevent the paper from deflecting and wrinkling.

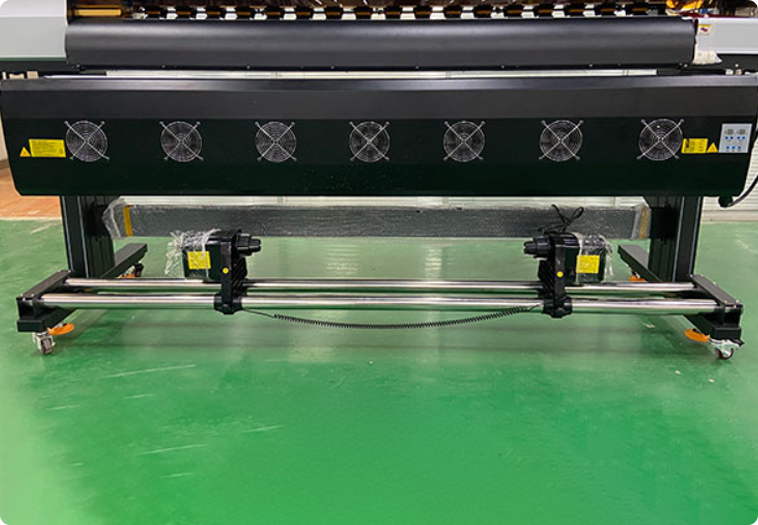

Feed & Take-Up System

The CO1900 is equipped with a Feed & Take-up System that can automatically rewind printing materials, enabling unattended production and managing production with the highest efficiency.

Ink Chain

The function of Ink Chain is to protect ink circuits, wires, and optical fiber lines from wear and tear after long-term use.

Dryer System

The CO1900 dye-sublimation printer comes with a drying system that can be synchronized with the printer, saving the post-drying process. Safe and convenient.

Advantages Of CO1900 Dye-Sublimation Printer

The CO1900 dye-sublimation printer is mainly used for fast, high-volume printing of clothing, textiles and soft signage, as well as other printed goods.

• The latest version of the board, built for high throughput:The latest version of the board is capable of processing large amounts of data quickly, allowing signals to be quickly communicated to the printhead via fiber optics

• High-precision image quality:It adopts Epson I3200-A1 print head to improve image quality and uses Epson precision dot technology. Achieve maximum color gamut when printing on different materials.

• Replacing accessories is easier:Users can replace the nozzle more easily and complete it in a few minutes. Ensures you can resume production in the shortest possible time.

Notes

• This product only uses original COLORIDO ink. We are not responsible if other incompatible inks are used to damage the nozzle.

• The printing speed of the printer depends on the selected PASS number. The higher the precision, the slower the printing speed.

• Consumable materials such as nozzles are not covered by the warranty.

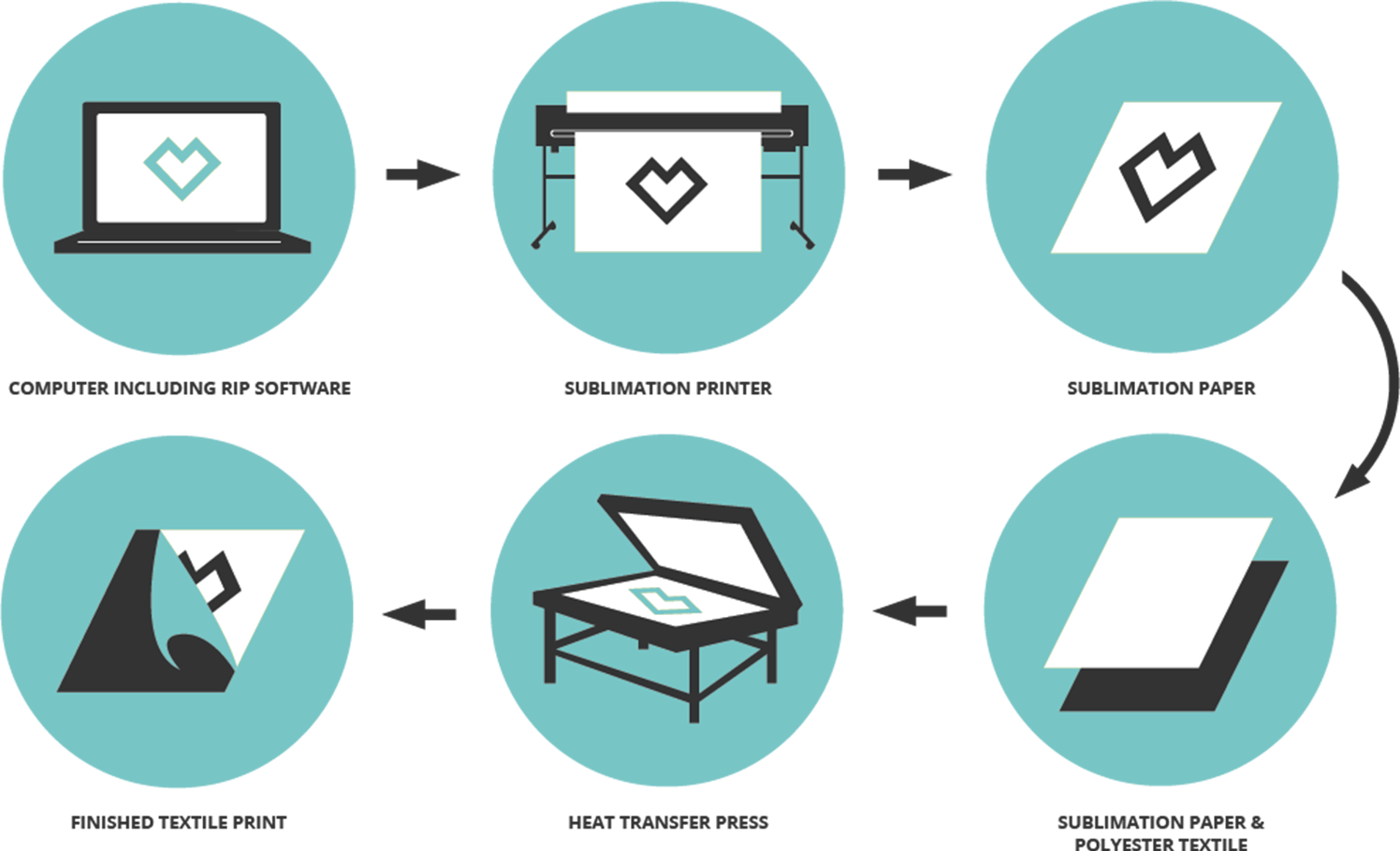

Dye Sublimation Printing Process

Dye Sublimation Printer is easy to operate. The following is the operation process of the dye sublimation printer.

FAQ

Dye-sublimation printers, starting at less than $10,000. Also, you will need additional equipment such as a heat press or cutting machine

Under normal use, the life of the printer is 8-10 years. The better the maintenance, the longer the life of the printer.

The adsorption capacity of inks of different materials also varies. Since the sublimation process involves the inks being chemically bonded to a material, decorated items permanent and washable.

Printing time and temperature depend on the material being printed. Generally, the following times and temperatures are recommended:

For polyester fabrics – 400F 40 seconds