Common problems and maintenance of digital printing machine nozzle

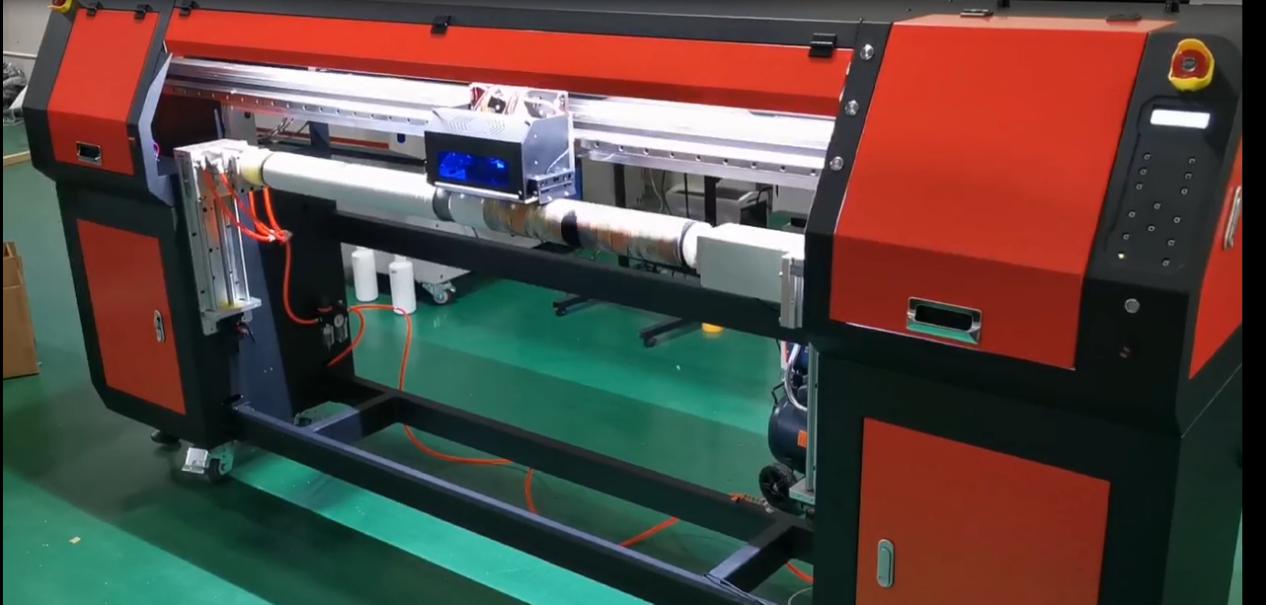

In the technical level, if we want high-quality products well-printed, nozzles of the digital printing machine must operate normally. With good-quality nozzles, the ink output can perform better and can be more refined. The nozzle is an indispensable core part of the digital printing production process. It is also a relatively expensive component

However, if the operation is improper, the nozzle is more likely to have a problem, so what are the reasons for the failure of the nozzle of the digital printing machine?

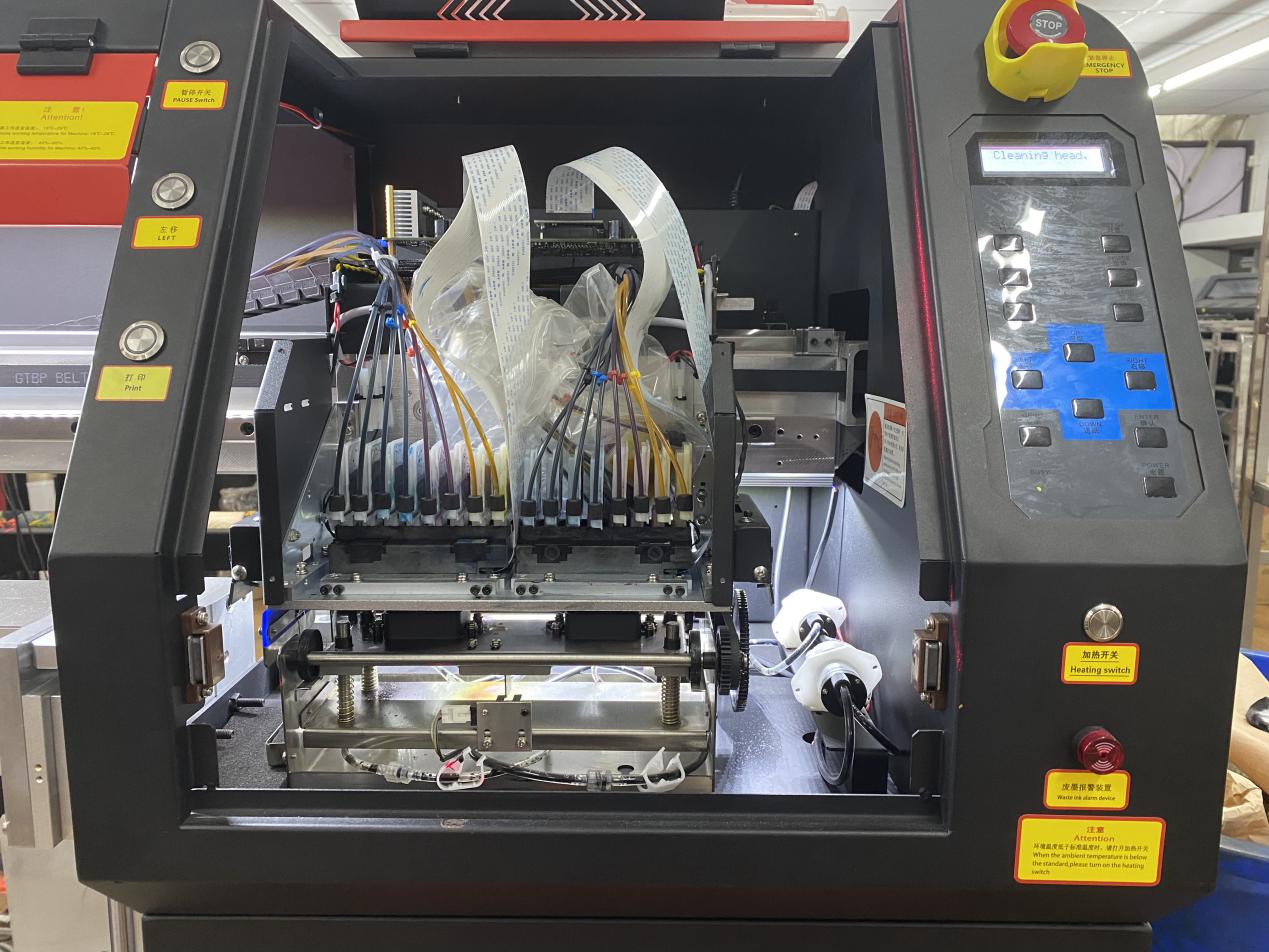

First of all, everyone should know that ink is a kind of liquid that is easy to evaporate, and it is easy to be volatile in the air to clear solid materials. In printing, the ink must be evaporated into the air to make the picture dry. Therefore, the common nozzle failure is the nozzle blockage, which is due to ink accumulation in the nozzle holes on the outside. Then there are four main reasons for the failure of the nozzle.

The first reason is that during the daily use of the nozzle of the printing machine, when the nozzle ejects ink to the medium, it is inevitable that some ink will remain around, and this part of the ink will inevitably remain around. After drying in the air, solids are formed, and over time the accumulation of solids will make the nozzle holes smaller and cause the blockage of nozzle hole.

The second reason for the failure of the nozzle: The aging of the electronic components of the drive circuit and the accumulation of too much dry ink dirt may affect the voltage of the drive nozzle, resulting in the situation that the nozzle does not output ink or the ink output is unstable.

The third reason for the failure of the nozzle: The nozzle is not protected when the ink is replaced, and the bump or damage will also affect the ink jet state of the nozzle.

The fourth reason: Using the nozzle for a long time will cause the ink to stay in the nozzle for a long time, especially the equipment that is frequently shut down due to the unsaturated period of the order and it is easy to be adsorbed on the internal filter or the inner wall of the ink channel. So the cross-section of the ink flow can be small, resulting in the phenomenon that the nozzle does not emit ink.

In order to make the nozzle work more stable and smooth, regular maintenance and cleaning are essential!