Seamless printing socks adopt advanced seamless printing technology and high-quality fabrics, showing a very fashionable design, comfortable and natural enjoyment, it is the best choice for you to wear.

View MoreIn recent years, Print on Demand socks have become a trend , for example customs face socks , customs picture socks and custom with logos . Socks printers are specifically designed for digital printing on socks. Compared to traditional sublimation socks, using a socks printer has significant advantages. Through socks printing machine , The socks can perfectly present the design without any visible seam , thereby giving it a unique significance .

Compared with traditional jacquard socks, the sock patterns printed by the sock printer are rich and varied, and at the same time, it can satisfy some pattern effects that traditional jacquard cannot present, such as tie-dye socks, gradient colors, etc.

View MoreDigital printing socks and thermal transfer socks are different in production process and wearing experience. Digital printing socks are printed by stretching the socks on a roller, the ink can penetrate into the yarn, and the socks will not appear white when worn. Thermal transfer socks directly transfer pictures to the surface of socks through high temperature, so the white part may be exposed when the socks are stretched, and the wearing comfort is not as good as digital printing socks.

Sublimation Socks

Digital Print Socks

The digital printing socks adopt advanced 360-degree seamless digital printing technology, so that the pattern fits perfectly at the seams without any seam marks. In contrast, heat transfer socks will be squeezed during the production process, and a clear seam will be formed in the middle, which will have a certain impact on the appearance.

Digital printing socks

Sublimation Socks

Digital printing socks use digital direct printing technology to print on the surface of the socks to ensure the quality and clarity of the pattern. Not only that, there are no extra threads on the inside of the socks, making them more comfortable to wear.

Digital Print SocksInside

Jacquard SocksInside

Digital printing socks have a wide color gamut and can achieve rich and colorful pattern effects, including arbitrary colors, complex graphics and gradient colors. Jacquard socks usually use jacquard technology, which is relatively limited in design and can only produce simple patterns and patterns. Due to stronger technical support, digitally printed socks can present more diverse designs and patterns.

Digital Print Socks

Jacquard Socks

Our socks printer is very flexible, there is no minimum order quantity (MOQ), you can print a pair of socks at will, fast and efficient, it only takes one minute to complete. Through seamless printing technology, the perfect connection of patterns can be achieved, no matter what the design is, we can achieve it. Allowing you to express yourself however you want with free expression of color.

CO60-100PRO is the latest double-arm rotary sock printer developed by Colorido. This sock printer is equipped with four Epson I1600 print heads and the latest visual positioning system.

CO80-210pro is the latest four-tube rotary sock printer developed by the company. This device is equipped with a visual positioning system. The four-tube rotary system can produce 60-80 pairs of socks per hour. This sock printer does not require upper and lower rollers. The carriage is equipped with two Epson I1600 print heads, which have high printing accuracy, bright colors, and smooth pattern connections.

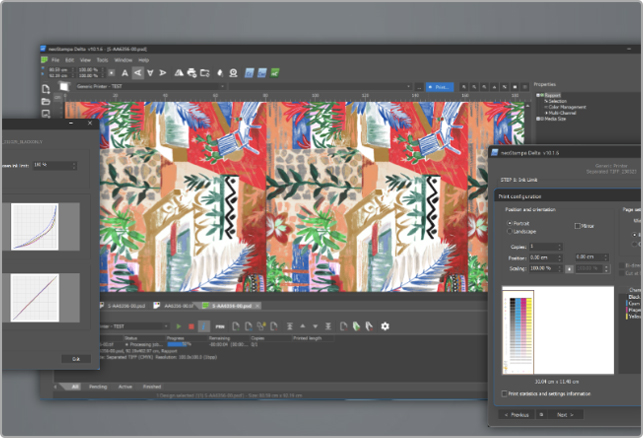

CO80-1200PRO is the second generation socks printer of Colorido. This socks printer adopts spiral printing. The carriage is equipped with two Epson I1600 print heads. The printing accuracy can reach 600DPI. This print head is low-cost and durable. In terms of software, this socks printer uses the latest version of rip software (Neostampa). In terms of production capacity, this socks printer can print about 45 pairs of socks in one hour. The spiral printing method greatly improves the output of socks printing.

Colorido has been operating digital printing equipment for 8 years. During this period, we continuously updated iterative equipment, continuously improved the technical level, and improved the after-sales team. We are ready to serve you better. Technical After-Sales Team

We have established a complete production chain to simulate the actual production situation of customers and produce socks of various materials. This enables us to pre-configure printing solutions for different materials for our customers.

Our RIP software uses top brands in the textile industry. Compared with other software, using this RIP software has wider broad areas of color which can increase the clarity of printed matter by more than 30%.

In order to provide customers with better color schemes, we continuously adjust and explore ink formulations, and update color configuration plans from time to time.

Our After-Sale service team eliminates the effects of time difference. Let us know when you need help, we are available here for 24 hours/ per day.

At Colorido, we have kept each generation of machines since the first machine was sold. For any customers who have needs, we will simulate the problems encountered by customers in front of the corresponding machines in order to find solutions faster.

neoStampa's color management engine ensures accurate and consistent color reproduction. This is crucial for achieving high-quality prints with vibrant and true-to-life colors.

We understand the variability of different sock styles and materials so we can provide individual solutions.

neoStampa's color management engine ensures accurate and consistent color reproduction. This is crucial for achieving high-quality prints with vibrant and true-to-life colors.

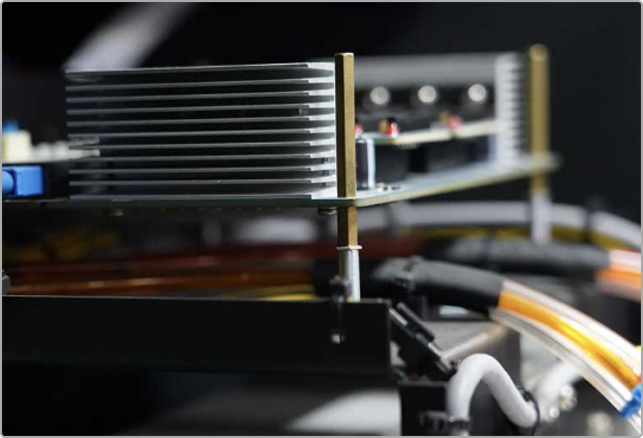

We opted for industry-leading mainboard , efficient data transfer and fast response times.

How to make Polyester socks

Input the ready RIP file to the

printing software and start for printing.

Put the printed socks into the oven to get the color fixation, the temperature at 180 ℃ time 3-4 minutes

Pack up the printed socks and send them to the customer. The whole process of polyester socks is finished