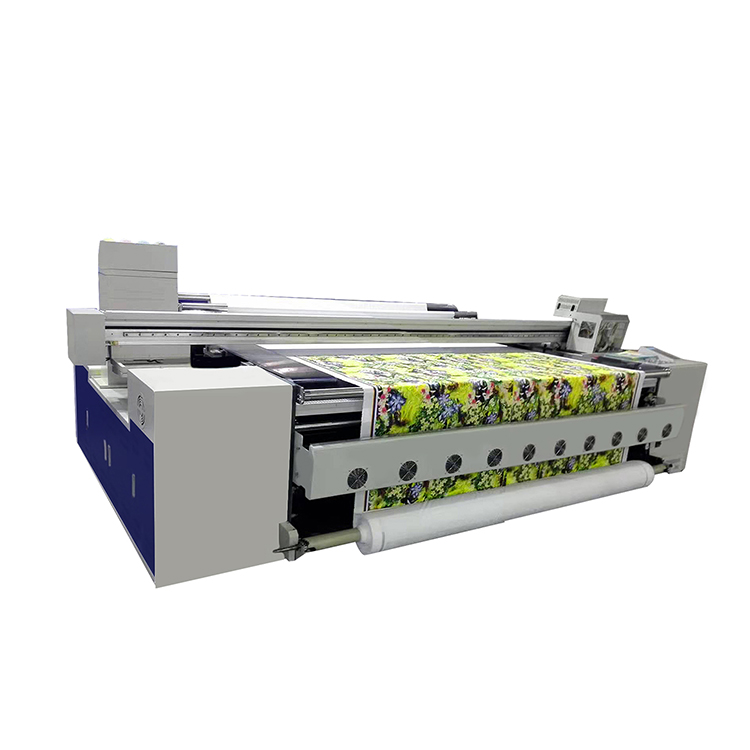

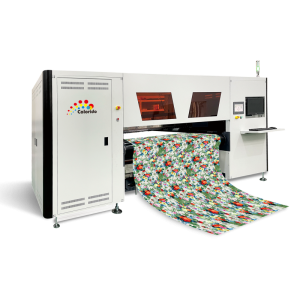

Digital Belt Textile Printer 1.8m Plotter Belt Digital Printing Machine

(1)Suitable for a variety of small batch production.

(2)Material feeding,feeding,printing,drying,and winding integrated into an organic whole,convenient and quick.

(3)Professional conduction band transmission system is equipped with guide with automatic cleaning,drying,to guarantee the continuous printing process sprocket surface clean and printing precision.

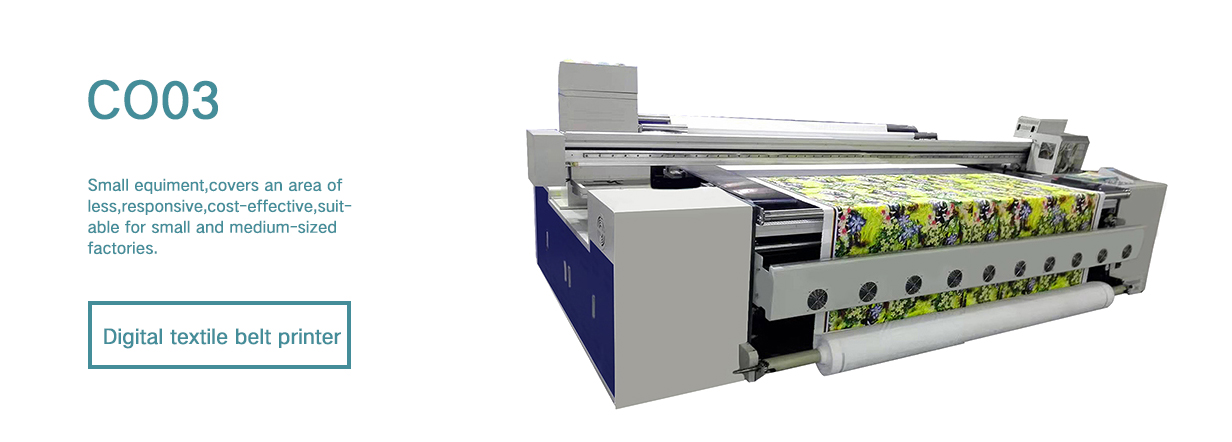

(4)Small equipment,covers an area of less,responsive,cost-effective,suitable for small and medium-sized factories..

Product Description

Parameter

-

Textile belt printer with Epson heads Model CO-03 Print head Four Epson DX5 Print head qty 2pcs/4pcs/8pcs Printing width 1800mm/2600mm/3200mm Max fabric width 1850mm/2650mm/3250mm Suitable fabrics thickness 2~30mm adjustable Suitable fabrics types Knitted or woven cotton, linen, silk, wool, polyester, nylon etc. Ink type Reactive, Acid, Sublimation, Pigment ink Ink colors 10colors: C, M, Y, K, LC, LM, Grey, Red, Orange, Blue Printing Speed (4colors production mode 4pass) Head model Epson DX5 Epson 5113/4720 2heads 30sqm/h 50sqm/h 4heads 60sqm/h 90sqm/h 8heads 120sqm/h 180sqm/h Cleaning Method Auto positive cleaning system Take up and Drying Belt continuous transport, automatic fabric taking up system, infrared dryer Work Station Win10 64bit CPU:Inter Core i7 6700K HD: 1T RAM:32GB RIP Software Wasatch/Neo Stampa Image type JPEG, TIFF, BMP file format/RGB, CMYK color mode Power Supply 380V±10% 3Phase 5Wire Frequency 50HZ±10% Consumption Epson 2heads Less than 6KW Epson 4heads Less than 11KW Epson 8heads Less than 16KW Compression air Air flow above 0.3m3/min, Air pressure above 6KG Working Conditions Temperature 18ºC-28ºC, Humidity 50%-70% Equipment Dimensions 1800mm 2600mm 3200mm 3500*2500*1700mm 4300*2500*1700mm 4900*2500*1700mm Weight 1250kg 1900kg 2200kg Remark: All models are subject to physical object

Product Description

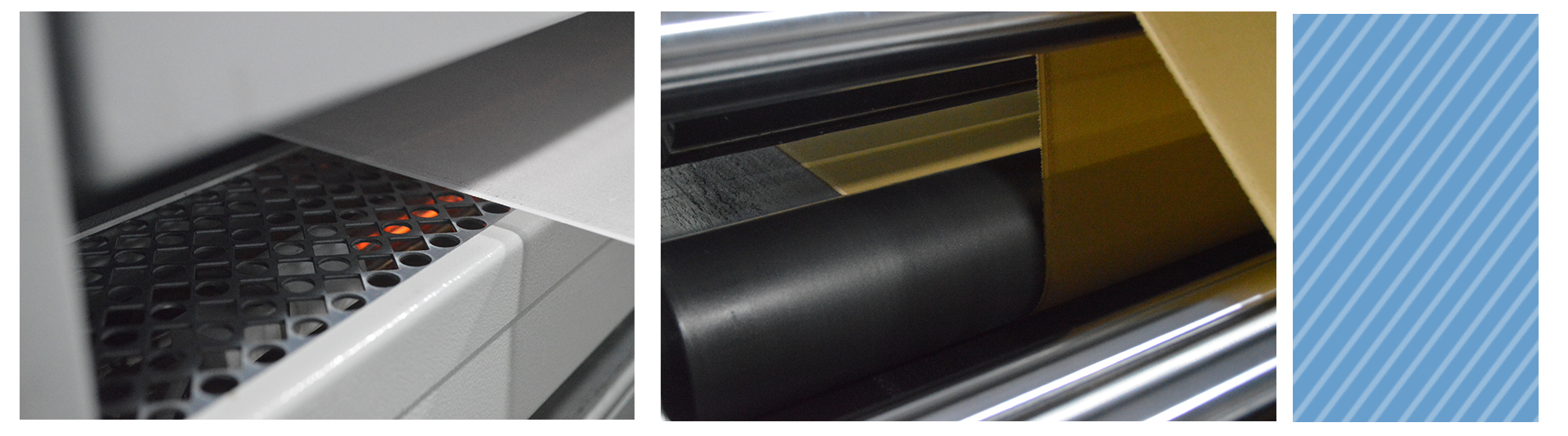

Detail

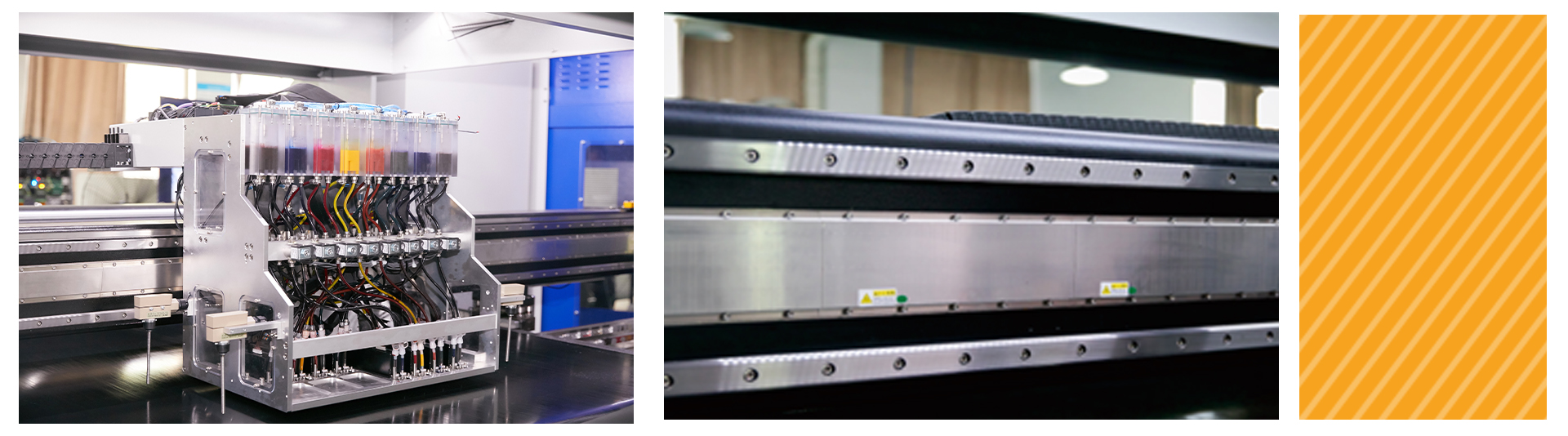

Max 32 heads carriage Maglev guide

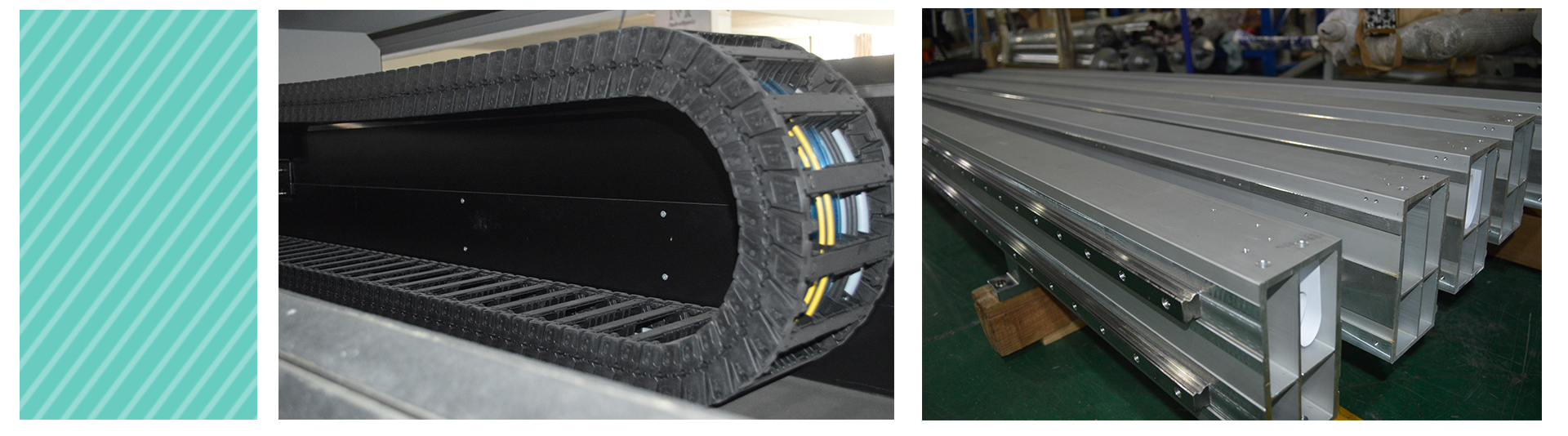

German import towline Japanese import guideway

Drying system Oil conduction roller

Individual control system for dryer LCD monitor

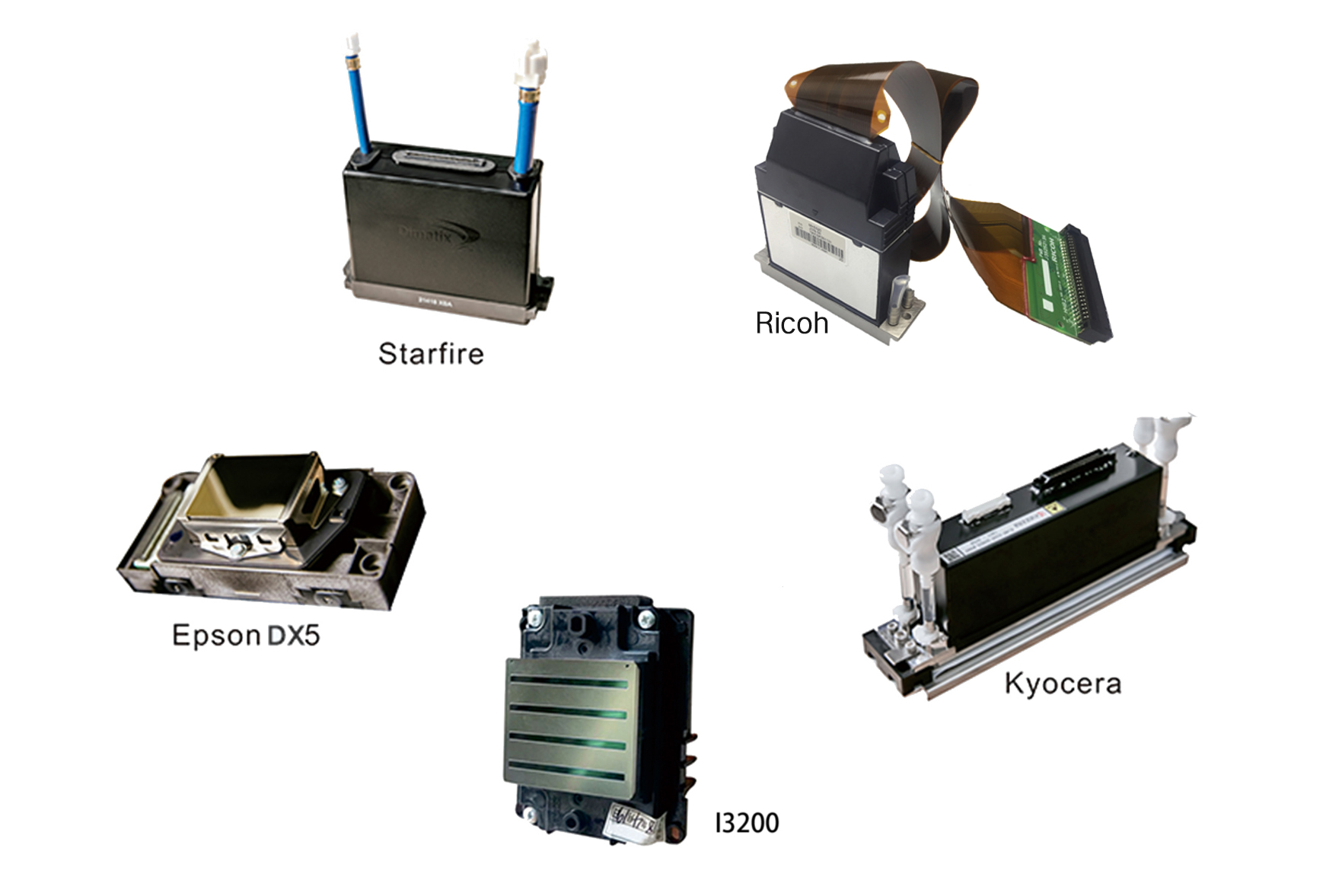

Print Head Show

Print Head

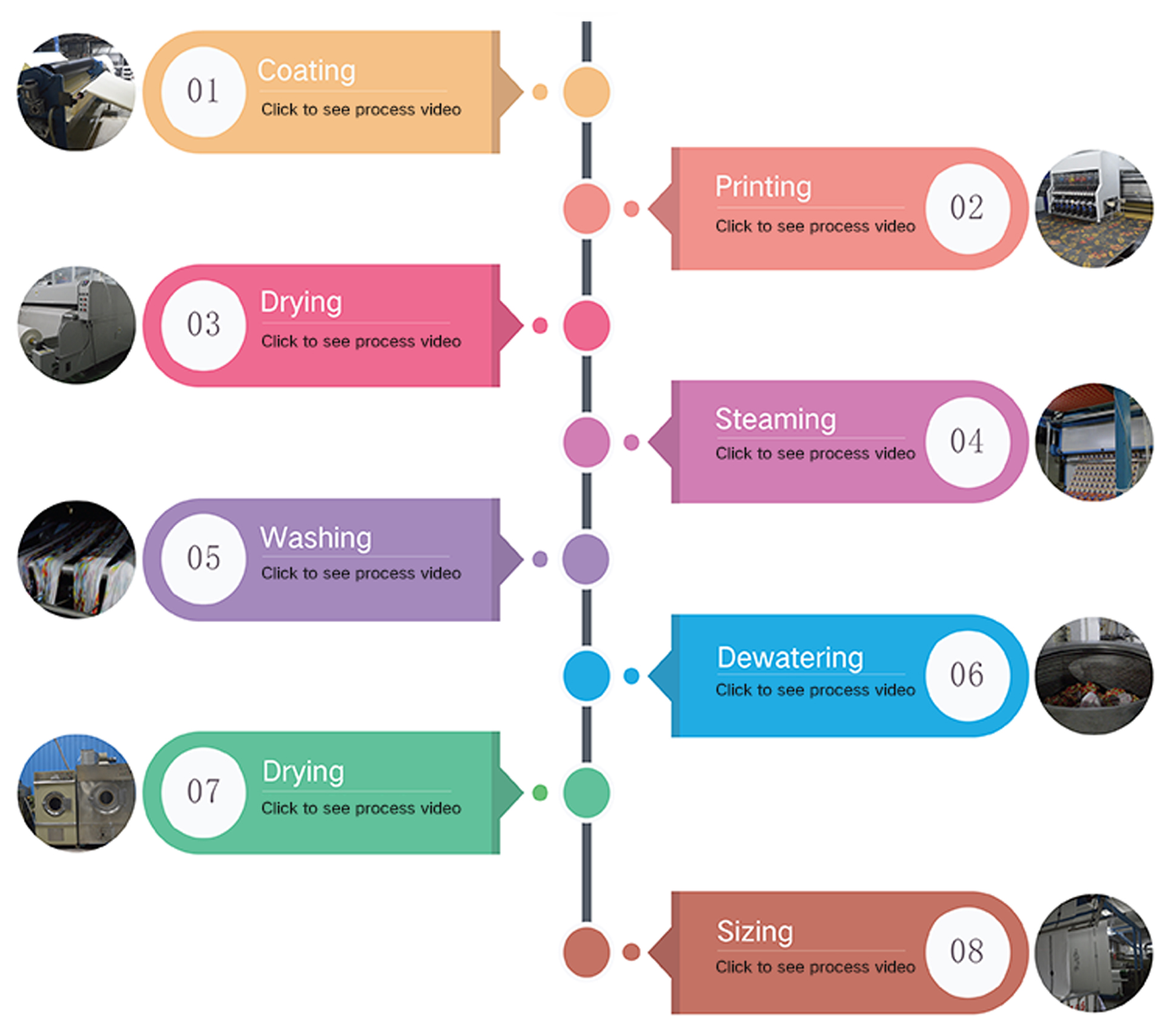

Processing

Customer Workshop

Production