factory Outlets for 2019 China New Design China Working Safe Gloves Machine for Work European Standard Anti Slip Soft Silicone Ink for Socks Dotting Printing 1 Color 24 Pallet Sock or Glove Screen Printer for New York Factory

Out of Stock

factory Outlets for 2019 China New Design China Working Safe Gloves Machine for Work European Standard Anti Slip Soft Silicone Ink for Socks Dotting Printing 1 Color 24 Pallet Sock or Glove Screen Printer for New York Factory Detail:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for 2019 China New Design China Working Safe Gloves Machine for Work European Standard Anti Slip Soft Silicone Ink for Socks Dotting Printing 1 Color 24 Pallet Sock or Glove Screen Printer, The concept of our organization is “Sincerity, Speed, Provider, and Satisfaction”. We are going to follow this concept and earn more and more customers’ satisfaction.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Anti Slip Soft Silicone Socks Dotting Printing, China Working Safe Gloves Machine, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products and solutions!

Product Description

| CO 80-1200(single roller) | CO 80-600(dual rollers) | CO 80-800(4 rollers) | ||

| Print Method | 1/2pcs EPSON DX5 Print head | |||

| Print Resolution | 720dpi*720dpi/360dpi*720dpi | |||

| Printing length | 1200mm*1 | 600mm*2 | 800mm*4 | |

| Printing diameter | 80~500mm | 80~200mm | 80mm | |

| Print Speed | 500pairs/24hr | 600pairs/24hr | 900pairs/24hr | |

| Suitable Fabric | Cotton,Linen,Wool,Silk,Polyester etc all other fabrics | |||

| Color | 4COLORS /6 COLORS/8 COLORS | |||

| Ink Type | Acidity,Reactive,Disperse,Coating Ink all compatible | |||

| File type | TIFF, JPEG,EPS,PDF etc | |||

| Rip software | Photoprint, Wasatch, Neostampa, Ultraprint | |||

| Environment | Temperature 18~30℃,Relative humidity 40~60%(non condensing) | ||

| Machine size | 3050*580*1280mm/300kg | 2700*550*1400mm/300kg | 2550*2000*1550mm/650kg |

| Package size | 3100*880*1750mm/400kg | 2870*880*1750mm/400kg | 3050*1920*1720mm/750kg |

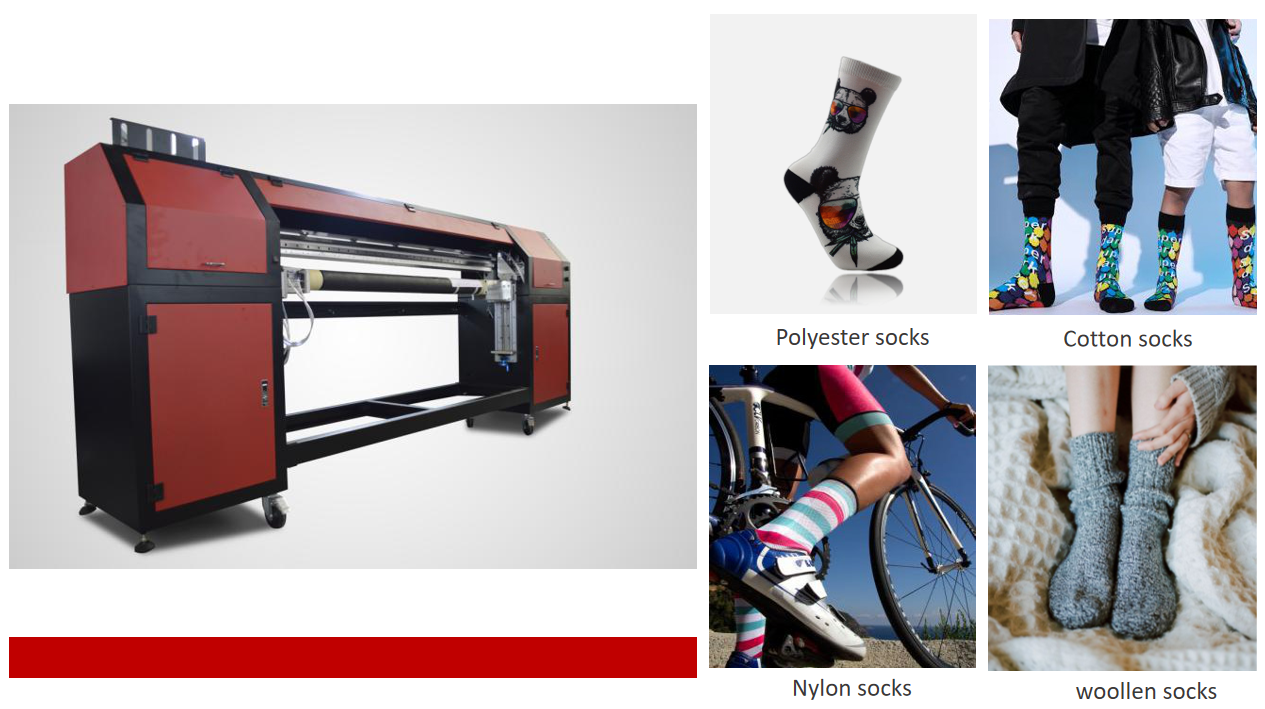

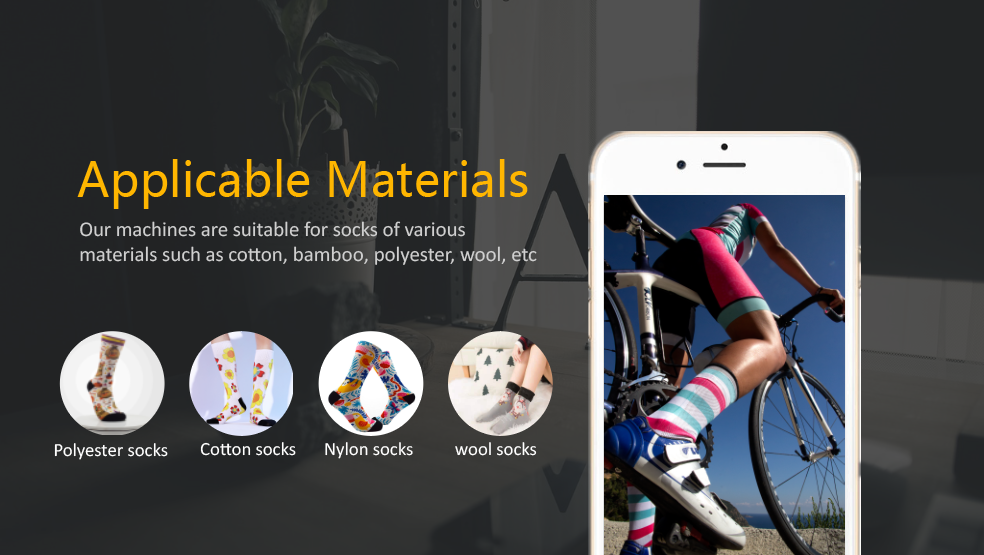

Our machines are suitable for socks of various materials such as cotton, polyester, wool, etc

YOU CAN FIND BELOW ANSWERS

Why choose 360 seamless printing?

What can we print?

Printer parameter/details

Printer package/delivery

Why choose Colorido?

Why choose 360 seamless printing?

No limit for the MOQ / Design / Colors

Show Dtails

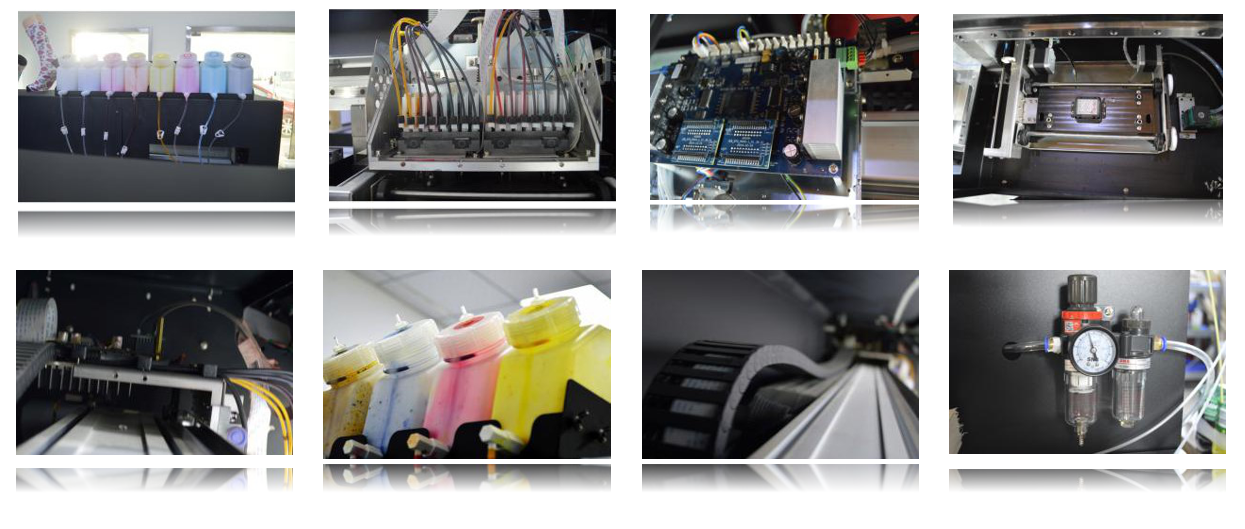

Every part is carefully designed and debugged so that you can use it easily

Youtube link

Cotton socks printing whole processes :

https://www.youtube.com/watch?v=F3lnVIPOGf4&feature=youtu.be

360 socks printing video (polyester socks)

https://www.youtube.com/watch?v=Q8YMXm21qUg

https://www.youtube.com/watch?v=xIKJrc-7dsw

360 Seamless underwear printing ,Rotary printer

https://www.youtube.com/watch?v=VGsVv2yeJo8

Digital socks printing production

https://youtu.be/8R1T_Rv6sfg

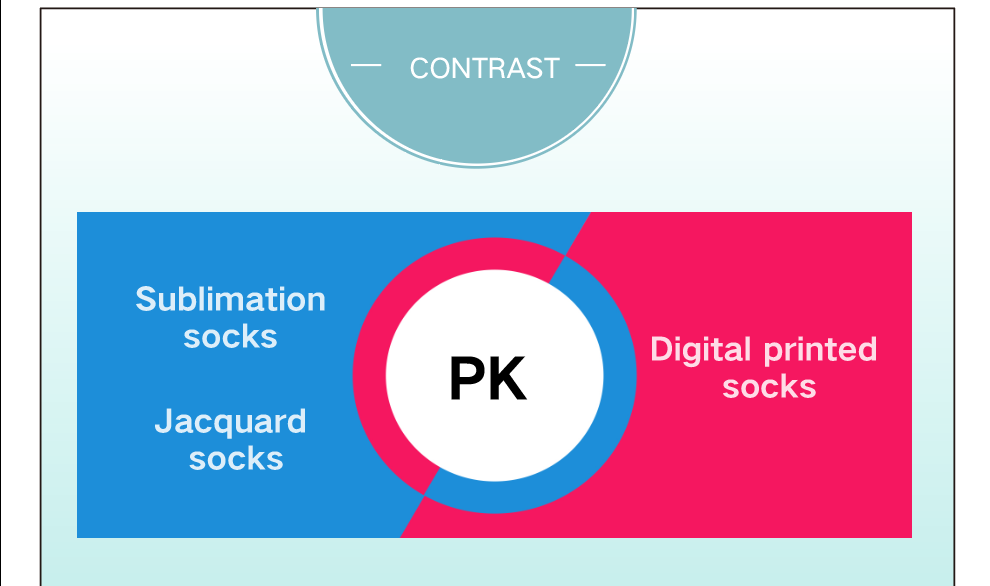

SUBLIMATION PRINTING TECHNOLOGY 360°DIGITAL PRINTING TECHNOLOGY

Due to heat pressing, 2sides joint leak white. The continuity and integrity embodiment design;

Generate obvious defect “impression” No indentation,more perfect;

Color difference of Durability, white phenomenon is serious. High color permeability,solve the white phenomenon

TRADITIONAL JACQUARD SOCKS 360°DIGITAL PRINTING TECHNOLOGY

Many threads inside that make uncomfortable when wear No additinal threads inside

Color is rigid; image is limited by color Much more comfortable when wear Printed color are more vivid

3D effects More attractive

What can we print?

Applicable Materials

Our machines are suitable for socks of various

materials such as cotton, bamboo, polyester, wool, etc

Product Description

1. It is suitable for any material with wide compatibility.

2. No plate-making, fast printing and low cost, you can use a variety of output software to support a variety of file formats.

3. Equipped with professional color management software, you can change the color anytime and anywhere without paying extra fees.

4. One-step completion, i.e. print-and-fetch, to meet the needs of rapid production of finished products.

5. Printing a large number of units can be matched with template printing, time-saving and labor-saving, full-color image, complete at one time, progressive color completely achieves photo quality effect, accurate positioning, zero rejection rate.

6. It takes only 30 minutes to master and produce high-quality products without professional skills. 8. Computer operation, no personnel dependence, large upgrade space.

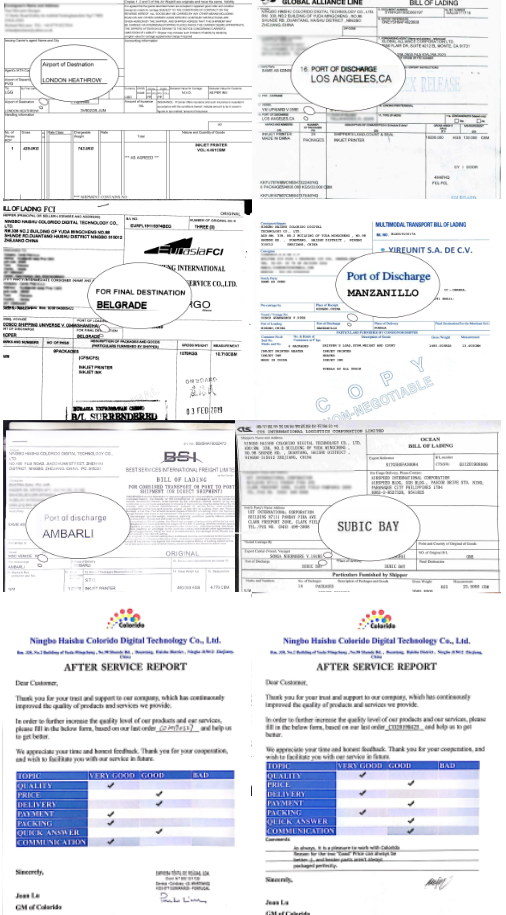

Why choose Colorido?

Strength shows

7 Days no reason to refund.

Provide SGS tested report NO fake, NO fake.

Provide variety of printing patterns with free.

Not 24 hours on line after sales service,but we committed to 16 hours

Product detail pictures:

Related Product Guide:

Understanding the Basics of Digital Textile Printers

Do You Know the Printing in China?

To create far more benefit for customers is our company philosophy; customer growing is our working chase for factory Outlets for 2019 China New Design China Working Safe Gloves Machine for Work European Standard Anti Slip Soft Silicone Ink for Socks Dotting Printing 1 Color 24 Pallet Sock or Glove Screen Printer for New York Factory , The product will supply to all over the world, such as: Barbados, Belgium, Montpellier, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

We have been looking for a professional and responsible supplier, and now we find it.