UV Printer Printing High-Quality Leather

A Must For High-End Leather Products Manufacturing

Printing Effect Display

Features & Principles

UV leather printing adopts ultraviolet curing technology to print on the leather material and harden it quickly, the printing effect is clear, delicate and long lasting, also it is not easy to fade, wear and tear. Meanwhile it can print a variety of patterns designs of the leather material with personalized customization of various leather products.

Characteristics of UV Personalized Experience

• Customized design: UV printing machine can print the images and designs on various materials, providing more options of customization designs. Whether it is DIY gifts, home decoration or personalized packaging, customers can create their own unique artworks.

• High-quality printing: UV printing machine adopts high-quality ink and technology, with which could achieve high-resolution and delicate color printing effect. This means users could get detailed, crisp prints on the leather material to show the unique personality.

• Various material options: UV printing machine could print on various material, such as on papers and photos, plastic, glass, wood, and even on leathers. This means users can print their favorite designs on any leather handcrafts.

• Anti-UV: UV printing machine uses coatings and ink curing system to provide strong durability. As a result, UV printing leather products could stay the color good fastness and durability once at outdoors or in environments exposed under strong sunlight.

• Quick reaction & Small volume Production: UV printing machine offers fast-production and customized services, so it is not only suitable for individual handcraft, but also for the commercial promotion with short productive producing period, high quality etc. advantages.

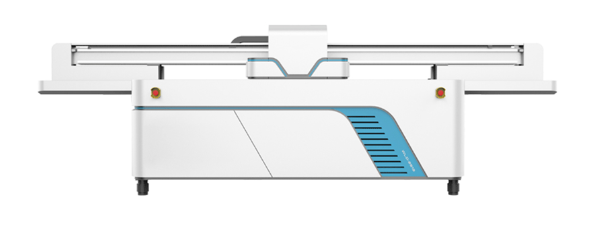

UV2513

Product Parameters

| Model Type | UV2513 |

| Nozzle configuration | Ricoh GEN61-8 Ricoh GEN5 1-8 |

| Area of platform | 2500mmx1300mm 25kg |

| Print speed | Ricoh G6 fast 6 heads production 75m²/h Ricoh G6 Four nozzle production 40m²/h |

| Print material | Type:Acrylic aluminum plastic board,wood, tile, foam board, metal plate, glass,cardboard and other plane objects |

| Ink type | Blue, magenta, yellow, black, light blue, light red, white, light oil |

| RIP software | PP,PF,CG,Ultraprint; |

| power supply voltage,power | AC220v, hosts the largest 3000w, 1500wX2 vacuum adsorption platform |

| lmage format | TiffJEPG,Postscript3,EPS,PDF/Etc. |

| Color control | In line with international ICC standard, with curve and density adjustment function, using ltalian Barbieri color system for color calibration |

| Print resolution | 720*1200dpi,720*900dpi,720*600dpi,720*300dpi |

| operating environment | Temperature: 20C to 28 C humidity: 40% to 60% |

| Apply the ink | Ricoh and LED-UV ink |

| The machine size | 4520mmX2240mm X1400mm 1200KG |

| Packing size | 4620mmX2340mm X1410mm 1400KG |

Workflow For Leather Printing

The following is the general process of making Leather by UV printer

1. Prepare the leather material, after pre-treatment of cleaning, the surface is smooth and flat, which is convenient for printing preparation.

2. Make designs properly and input it into printing software.

3. Use the color management, adjust the printing parameters and colors, and ensure that the printed patterns are accurate.

4. By using the printing software, select the print head and ink cartridge, set the white ink and color ink printing functions, and select the appropriate printing mode and settings.

5. Put the leather material on the printing platform to start printing, ensure the position and flatness of the leather, and pay attention to the nozzle and distance of the printer.

6. After the printing is completed, take out the printed leather, put it into a special curing room, and cure the printed pattern with the UV light.

6. Finally, drying and post-processing can be carried out to ensure the appearance and quality of printed matter.

Precautions:

1. UV ink should be storage properly and replaced in time.

2. Use UV lamp to ensure that the ink is cured completed, and you can choose to strengthen the lamp if necessary.

3. Ensure printer and operator safety protection. Follow strictly the printer's specifications and guidelines.

4. When using a UV printer, pay attention to indoor ventilation and wear safety protection equipment and avoid the skin touching with UV ink.

After-sales service

As a UV printer supplier, we provide the following 5 points of after-sales service guarantees, while ensuring the stable operation of the equipment, we provide customers with first-class after-sales service and technical support:

1. Provide professional technical support: We have professional technicians who can assist customers to solve various problems encountered in the process of using UV printers, including both hardware& software problems. We will deal with customer feedback as soon as possible and give solutions to ensure the operation for the production could be kept continuously.

2. Provide comprehensive warranty service: We provide comprehensive warranty service, covering issues such as equipment failure and repair. During the warranty period, customers can enjoy free equipment repair and replacement services, providing a good experience.

3. Regular maintenance: We will regularly send professional technicians to maintain the customer's equipment to ensure the normal operation and good condition of the equipment. We will provide a corresponding maintenance service plan according to the usage of the equipment, and carry out all-round maintenance and inspection of the equipment on a regular basis.

4. Equipment training and guidance: We provide training and guidance on equipment operation and maintenance to help customers better use and maintain equipment. We can provide customers with online training and on-site training to ensure that customers master the normal operation and maintenance technology of equipment.

5. Provide device upgrades and updates: We will continue to provide device upgrades and updates to improve device performance and functionality. We will pay attention to the performance and stability of the equipment, and launch updates and upgrades in time to ensure that the equipment continues to remain competitive.

We always take good care of the customs requirements as the first priority issue as our permanent service goal. We provide a full range of after-sales service guarantee, offer customers comfortable experience and worry-free.

Products Display