Digital printing refers to methods of printing from a digital-based image directly to a variety of media.[1] It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. It also allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression.[2] The savings in labor and the ever-increasing capability of digital presses means that digital printing is reaching the point where it can match or supersede offset printing technology’s ability to produce larger print runs of several thousand sheets at a low price.

Digital printing refers to methods of printing from a digital-based image directly to a variety of media.[1] It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. It also allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression.[2] The savings in labor and the ever-increasing capability of digital presses means that digital printing is reaching the point where it can match or supersede offset printing technology’s ability to produce larger print runs of several thousand sheets at a low price.

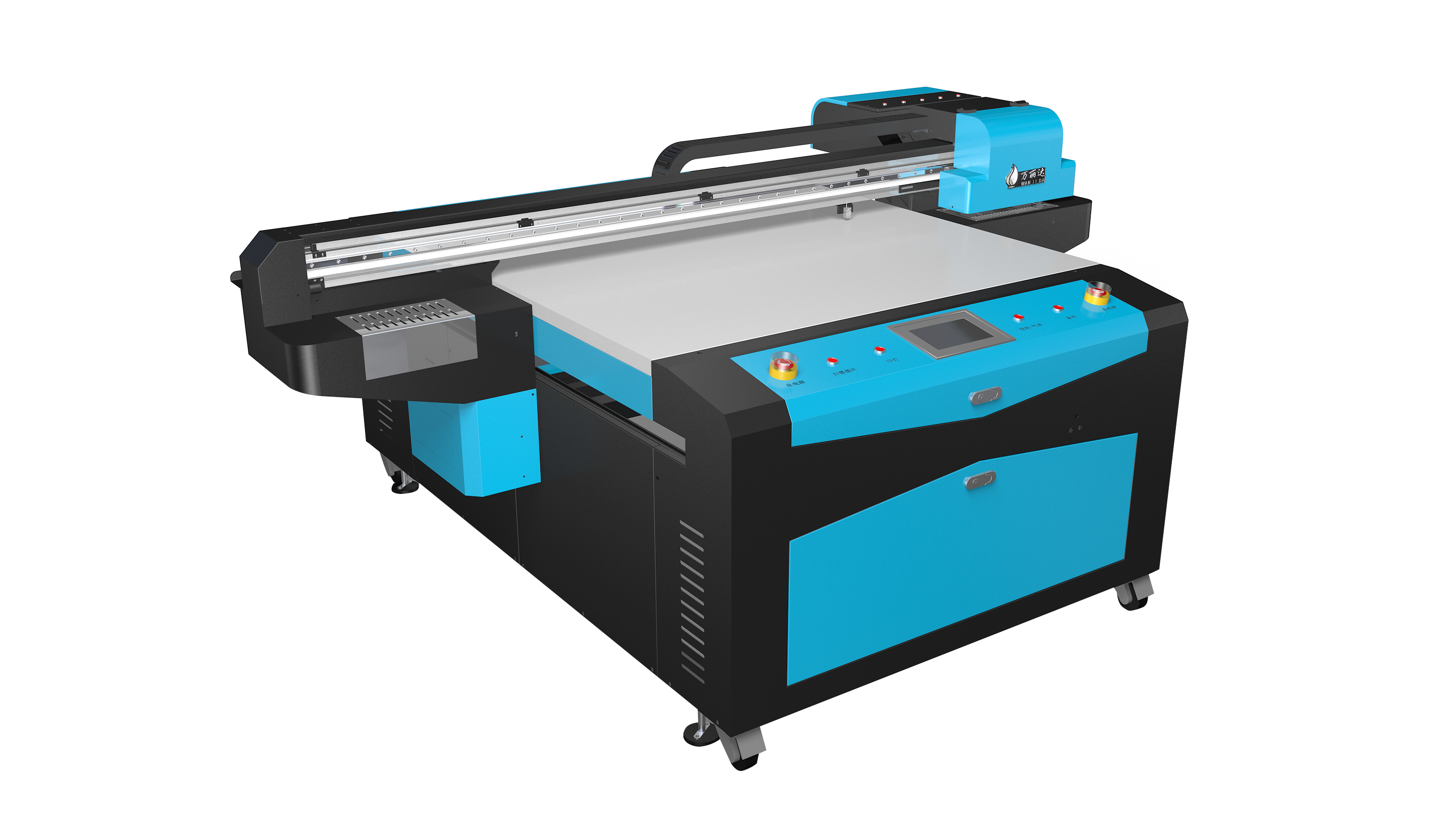

The greatest difference between digital printing and traditional methods such as lithography, flexography, gravure, or letterpress is that there is no need to replace printing plates in digital printing, whereas in analog printing the plates are repeatedly replaced. This results in quicker turnaround time and lower cost when using digital printing, but typically a loss of some fine-image detail by most commercial digital printing processes. The most popular methods include inkjet or laser printers that deposit pigment or toner onto a wide variety of substrates including paper, photo paper, canvas, glass, metal, marble, and other substances.

In many of the processes, the ink or toner does not permeate the substrate, as does conventional ink, but forms a thin layer on the surface that may be additionally adhered to the substrate by using a fuser fluid with heat process (toner) or UV curing process (ink).

In digital printing, an image is sent directly to the printer using digital files such as PDFs and those from graphics software such as Illustrator and InDesign. This eliminates the need for a printing plate, which is used in offset printing, which can save money and time.

Without the need to create a plate, digital printing has brought about fast turnaround times and printing on demand. Instead of having to print large, pre-determined runs, requests can be made for as little as one print. While offset printing still often results in slightly better quality prints, digital methods are being worked on at a fast rate to improve quality and lower costs.

Post time: Mar-02-2017