The custom printed socks not only have requirements for the knitting process of the sock toe. There are also some certain requirements for the thickness and flatness of socks.

Let’s see how it is!

Thickness of socks

For printed socks, it is required that the socks could not be too thin. Like the ladies stockings, that is not suitable for socks printing. Because the yarn is too thin with big mesh holes once stretching it. So once if it is under printing, ink would be flowed away, and nothing left over on the sock’s material. so, the printing pattern and effect would be invisible.

Therefore, it is required that the printed socks should be like 21’s yarn, or 32’s yarn, with 168N or 200N, then the thickness of the socks would be great for printing. Otherwise, even if the yarn of socks absorbs the ink, it will be just stay on top of the yarn and could not being delivered to the deep inside of the yarn, to get even color. But would be uneven color and pale outlook after printing.

On the other hand, if the socks are too thick, the sock yarn may not absorb the ink completely, or the ink just stay on top, it would easy causing the printed colors to be uneven and color not bright enough. Sometime you might find the ground yarn self-color being seen through.

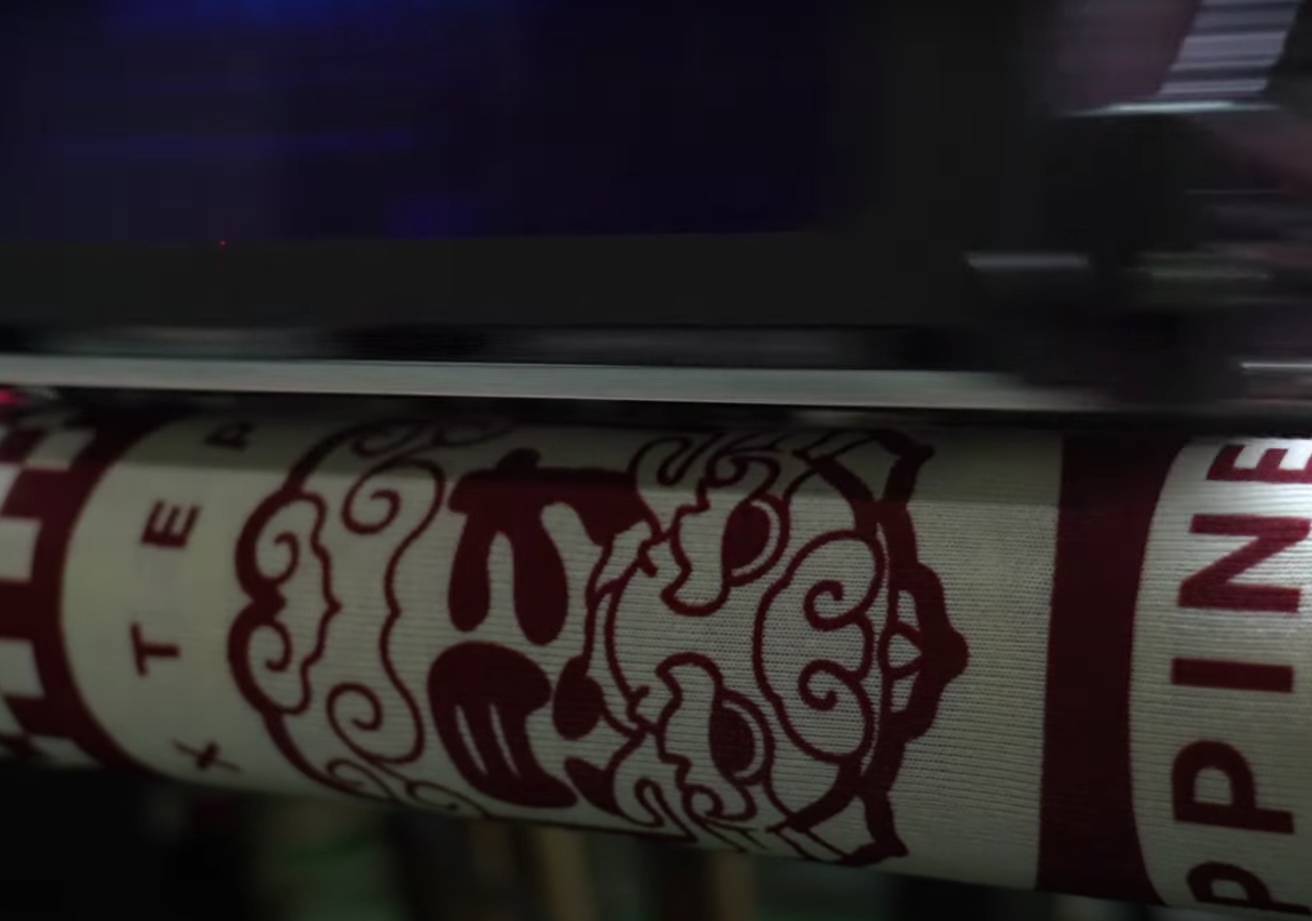

Smoothness of socks:When knitting socks, the needle tension must be well controlled to keep the entire round to be flat and even gauge space. In this way, when printing, during the rotating of the roller is running, the height space between the socks to the printhead needs to be same and ensure nozzle would not be scratched by the socks fiber. So that the printed colors will be more uniform, there will be no differences in shades.

People would say: In order to prevent the nozzle from hitting the protruding surface of the socks, how about adjusting the height of the nozzle a bit higher? As everyone knows, this may cause ink flies, so the color might not be with high resolution. Also, it would be coming with high-low distance difference from the socks body to the printhead. Therefore, the color of different part of socks would be different then.

In addition, the flatness also depends on whether the elastic yarn at background of the socks would be knitted even or not. Otherwise, the surface of the socks will be like a layer of "white sesame" because the protruding elastic yarn is not absorbing the in color.

Ready for a new

Business Adventure?

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

200N/ 5gauge

Not 100% but once if the stocking is with some thickness, we can do the printing as well.

Post time: Nov-07-2023