Unique Digital Printed Seamless Garemnts Makes You Standing Out

(Digital printed seamless garments can be with personalized design

according to customer’s different requirement)

Nowadays, digitally printed seamless clothing is becoming more and more popular, the most prominent of which is the application of seamless clothing in sportswear, such as yoga leggings, seamless sports underwear, etc.

Digitally printed seamless garments could offer bright color and present excellent visual effects. With adopting fast printing technology, the production speed is fast, and also save the cost for print mold development.

The Unique Selling Point of Digital Printed Seamless Garments

• Fine Printing Process: Digital printing technology could achieve delicate printing design outlook. the area and color of ink dots ejected by each nozzle can be controlled, and the color is more natural, bring out more details with a high-quality visual enjoyment.

• Multi-Color Presentation: Digital printing technology can express plentiful colors, to ensure every garment looks vivid and colorful, expressing extra charming of personality, especially when you are doing exercises. Those expression for colors and details are indispensable to the traditional jacquard process.

• Perfect Connection Seam: Digital printing technology can realize seamless patterns without color difference and breakpoints, making the seamless garments look perfect.

Long-lasting And Durability: With high-quality digital printing technology and durable seamless knitting material, the seamless garments will maintain their vibrant colors after many times of washing, and the patterns will not be faded or damaged after long time wearing.

With digital printing technology, any complex patterns and designs could be fixed on seamless garments. Without any tedious process, seamless digital printing technology has become the first priority choice in the sports and leisure fashion wear.

Using digital printing technology, any complicated patterns and designs can be printed directly on the yoga pants without any tedious process.

Why Choose Digital Printing Seamless Garment

• Flexible Creation : Compare with traditional jacquard knitting seamless item, digital print-ing seamless brings potential possibilities for creative design idea.

• High Precision for Details: Digital printing seamless could reach high precision design art-work in details. While limitation for traditional jacquard technology is obviously. Personalized StyleElevation: Digital printing seamless garments have revolutionized young fashion and avid sports en-thuslasts likely. And the innovative creations provlde people a platform to express the unique per-sonallities by wearing digital seamless garment.

• Low Cost: Compare with traditional seamless garment industry, the cost of digital printing one decreased a lot without basic material MOQ requests and also printing mold development cost. Therefore, it becomes more commercial and efficient industry.

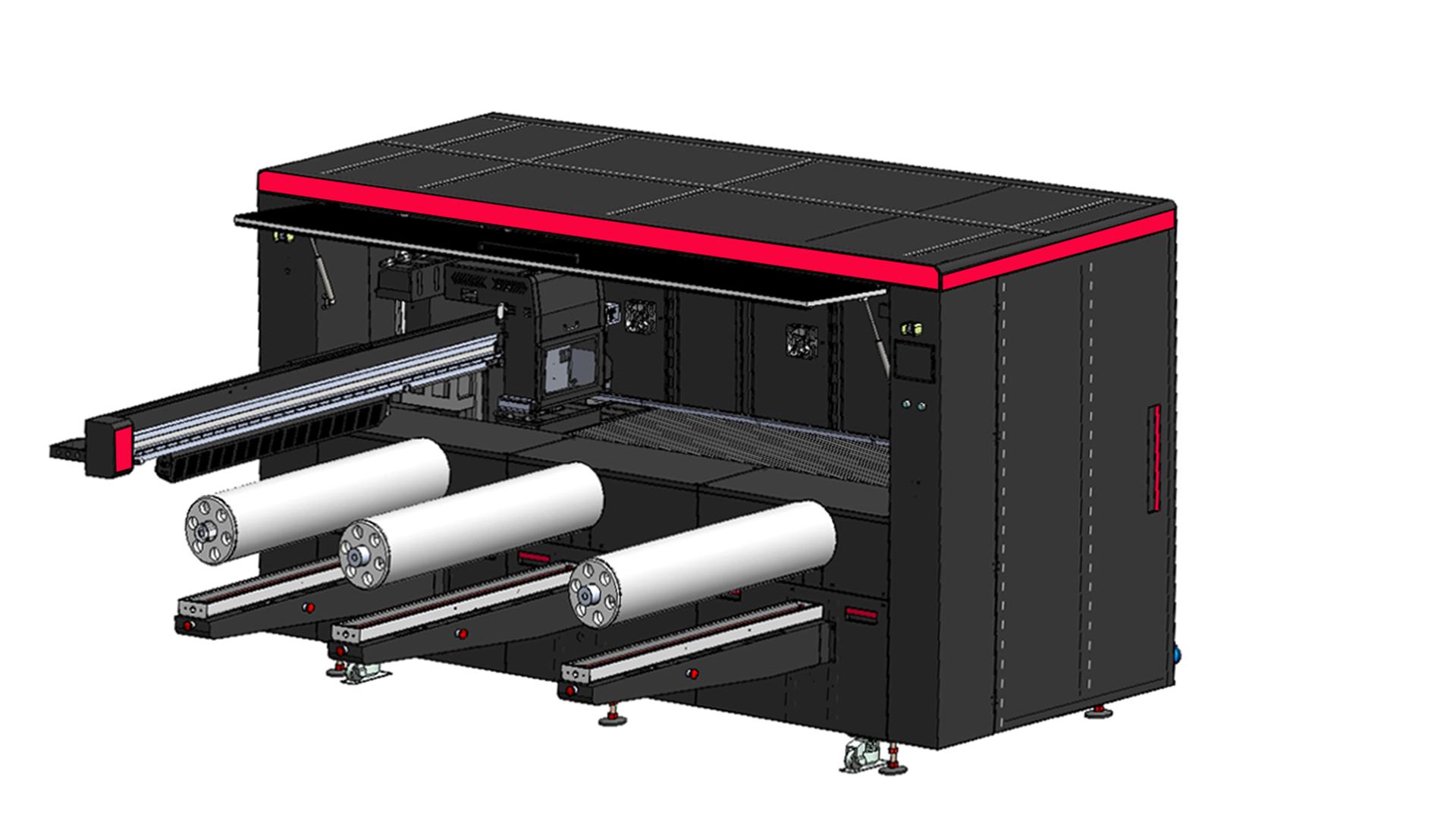

Multifunction-Yoga Printer

Product Parameters

| Print head model | EPSON DX5 |

| Print resolution | 720dpi*720dpi/360dpi*720dpi |

| Print area length | 500mm*4 |

| Print area diameter | 500mm |

| Suitable fabric | Polyester, linen, wool, silk, cotton etc |

| Color | 4 Colors /6 Colors/8 Colors |

| Recommended ink types | Acidic, reactive, disperse and coating Inks |

| Recommended file types | TIFF. JPEG, EPS, PDF Files at 3oo dpi or better |

| Rip software | Photoprint, Neostampa |

| Power | Single phase AC Earth wire 110~220V+10% 15A 5060HZ /1000W |

| Recommended environmental conditions | Temperature 25~30C,Relative humidity 40~6o%(non condensing) |

| Printer size | 3500*2300*2200MM |

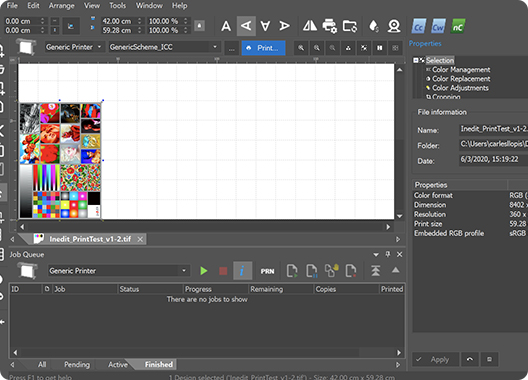

Designs & Artwork: According to the customer’s detailed request, artwork needs to be done by design software (such as Adobe Photoshop or Illustrator) to make readable file by the print software, of which could be recognized by final print equipment.

Color Management & RIP: Use color management software to adjust the color and ensure the image has the same color performance on final material.

Then input the well color-managed image into RIP software for processing.

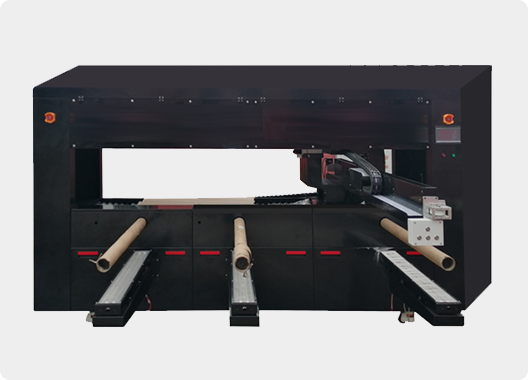

Printing: Select the ready RIP file into the digital printer for printing. Stable system support is the key point to get the high precision quality of images.

Drying& Finishing: The well printed products need to be dried in an oven to ensure the ink can be firmly attached to the fiber of the products. Based on different material, finishing step can be adjusted for fixation accordingly.

Product Display